From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

Find everything you need to make more informed decisions and advance your business, including Product Announcements, Articles, Case Studies, White Papers, Webinars, seminars and Videos, as well as our Knowledge Base, Mitutoyo Institute of Metrology and M3 Solution Centers.

147 Results - Clear filters

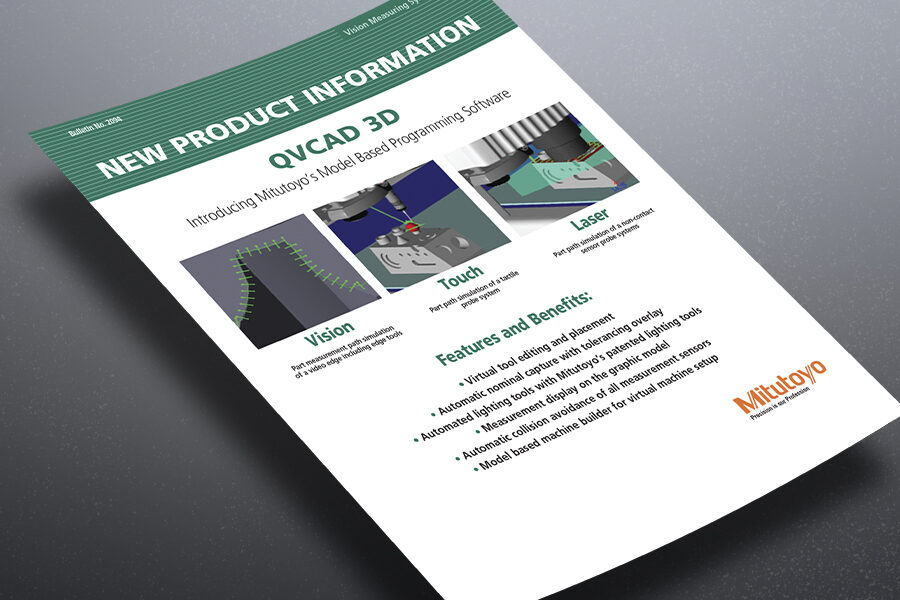

Access the complete Vision Measuring Sytems Section M of the Mitutoyo US-100 Catalog

Access the complete Coordinate Measuring Machine Section L of the Mitutoyo US-100 Catalog

Access the complete Test Equipment Section K of the Mitutoyo US-100 Catalog

Access the complete Form Measurement Section J of the Mitutoyo US-100 Catalog

Access the complete Optical Measurement Section I of the Mitutoyo US-100 Catalog

Access the complete Scales & DRO Section H of the Mitutoyo US-100 Catalog

Access the complete Sensor Systems Section G of the Mitutoyo US-100 Catalog

Access the complete Small Tools and Data Management sections (A-F) of the Mitutoyo US-100 Catalog

Mitutoyo Precision Measuring Machines Trusted Throughout the World.

New protective cases for your tools offer a modern alternative to our wooden cases. Versions include mechanical, standard Digimatic, or QuantuMike-based sets. QuantuMikes are just as accurate as standard Digimatic micrometers, but up to 4x faster. Empty cases are also...

The MDE Quantumike Micrometer offers rapid and precise measurements with its unique wider thread pitch, moving the spindle 2.0 mm per rotation — up to 4x faster than standard micrometers. It features exceptional accuracy with a ±1 μm permissible error,...

High accuracy, low uncertainty, and validated measurement methods are the reasons customers rely on Mitutoyo America Corporation.

The versatile Mitutoyo Rockwell Hardness Line-up includes models designed to accommodate any budget without compromising on quality or functionality. All models, including the HR-430 series, are equipped with an Automatic Brake and Process initiation system, which automatically applies your desired...

The Quick Scope QS-L system is a fully-featured, vision measurement system featuring a space-saving ergonomic design.

MeasurLink® Version 10 is an easy-to-use, data collection and real-time statistical process control suite. MeasurLink® supports Real-Time data collection with live SPC charts to alert operators, and additional alerts, analysis tools, and reports for Quality Control and Operations.

With this limited-time program, your move to a new, state-of-the-art Mitutoyo Roundness Measurement System could not be easier, faster or more budget friendly.

Sensors and Embedded Equipment provides an in-depth overview of their extensive range of sensor products, their diverse applications, and the industries that benefit from these cutting-edge tools.

Measurement solutions for a wide range of fields in the semiconductor manufacturing industry, which is growing rapidly following a shift to production of electric vehicles, expansion of services in line with the implementation of 5G, etc.

Mitutoyo offers solutions to measurement of a wide variety of lenses from research and development to pre production and mass production.

Mitutoyo offers solutions to measurement of a wide variety of electric vehicles from research and development to pre production and mass production.

To help the thousands of operators using legacy CMMs, we are pleased to offer a U.S.-based trade-in program. When you trade in your current CMM and purchase a new Mitutoyo CNC CMM, you will receive the latest technology, ensuring reliable...

New-generation ID series making measurement operations smoother and enhancing production quality.

From manual and automated to advanced and system-based systems, Mitutoyo offers a full line of Vision Measuring Machines that are highly accurate, built with quality components and feature the latest in optics technology.

With sophisticated edge detection capabilities, an illumination wizard, and advanced user-friendly software, the Quick Vision Series satisfies the demand for compactness, high accuracy, and vast performance in the field of non-contact dimensional measurement.

The 2-D non-contact Quick Image vision system features better operational efficiency and productivity, reliable quality and easy-to-use functions while providing highly accurate measurements.

The MiSCAN Vision System has a multiple sensor microscopic-form measurement system, using combined technologies of coordinate and vision measurement system technology.

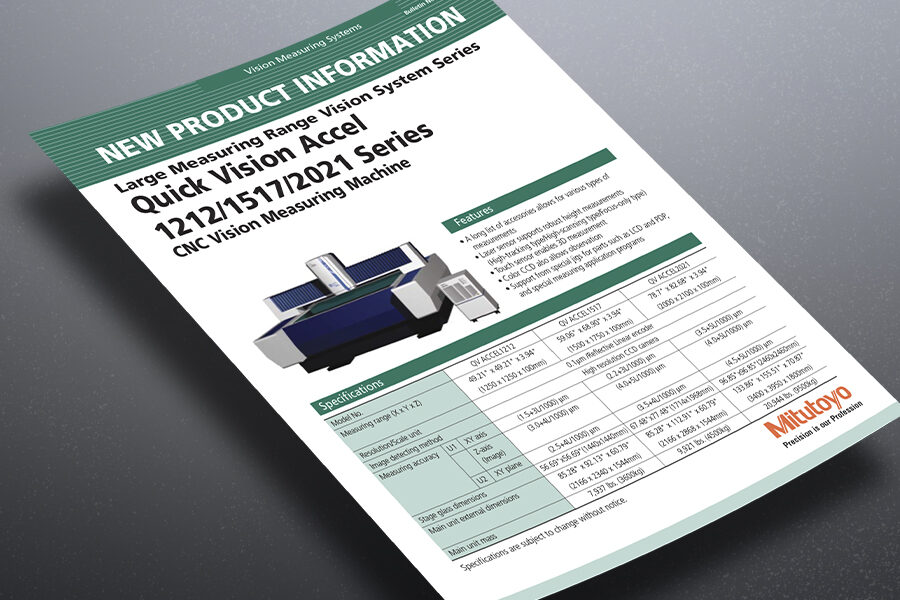

The large-format Quick Vision ACCEL CNC vision measuring system’s moving-bridge structure moves the X- and Y-axes faster for better measurement speed and efficiency.

For more than three decades KOMEG has been among the international innovation generators of sophisticated industrial measuring technique, setting important technological milestones and providing groundbreaking customer-specific solutions.

Points From Focus (PFF) is a Mitutoyo-developed optical data collection method that captures point data by focusing in the Z-axis.

The Series 570 Absolute Digimatic Height Gage. A New standard height gage providing reliable and smart measurement. This is an update of the height gage standard type that has gained a strong reputation in the manufacturing field.

Industrial inspection and quality control rely on precision measuring machines and precision fixturing alike. Reliable and repeatable fixture set-up is a basic requirement for successful and accurate measurement. Mitutoyo fixtures: For measurably better results.

As the scale moves with respect to the detector, the intensity of the light passing through the window in the index scale varies constantly.

MCubeMap Ver. 9 is 3D surface analysis software for surface roughness and vision measuring machines. Clear imaging of analyzed data using diverse computer graphics technologies.

Rockwell hardness testing machine series, 3 models to suit practically every application. HR-320MS is a Dual type hardness testing machine, HR-430R is a Rockwell hardness testing machine and the HR-430S is a Dual type hardness testing equipment.

The best shop floor CMM just got better. Now with 5-axis measuring, allowing increased throughput with reduced calibration time. PH20’s unique ‘head touches’ allow measurement points to be taken by moving only the head rather than the CMM structure.

The Mitutoyo PJ-Plus is a new series of profile projectors that utilize LED lighting and provides reliable measurements in manufacturing site environments.

With MCOSMOS, your coordinate measuring machines become efficient information centers – powerhouses of design, production, and quality control. Streamlined measurements, as well as convenient and reliable data, are at your fingertips throughout the production process.

With its high-resolution scale load cell developed uniquely by Mitutoyo that allows for high-precision test load feedback control and state-of-the-art design that delivers both aesthetics and usability on the ground, the new HR-600 Series enables hardness testing that defies conventional...

Roundtracer Flash is the perfect solution for accurate quality control in the laboratory as well as in the production environment.

High scanning rate (3200 scans/sec) and high accuracy, non-contact measuring systems, the laser scan micrometer (LSM) inspects small, fragile workpieces at a high temperature, even while in motion or vibrating.

The Mitutoyo MF and MF-U measuring microscopes are available in manual and motorized units. Each model is packed with features, functions and high magnifications for highly accurate measurements on miniscule-sized parts.

High-precision protractor makes accurate angle measurements on machines, molds and jigs and can be attached to a height gage.

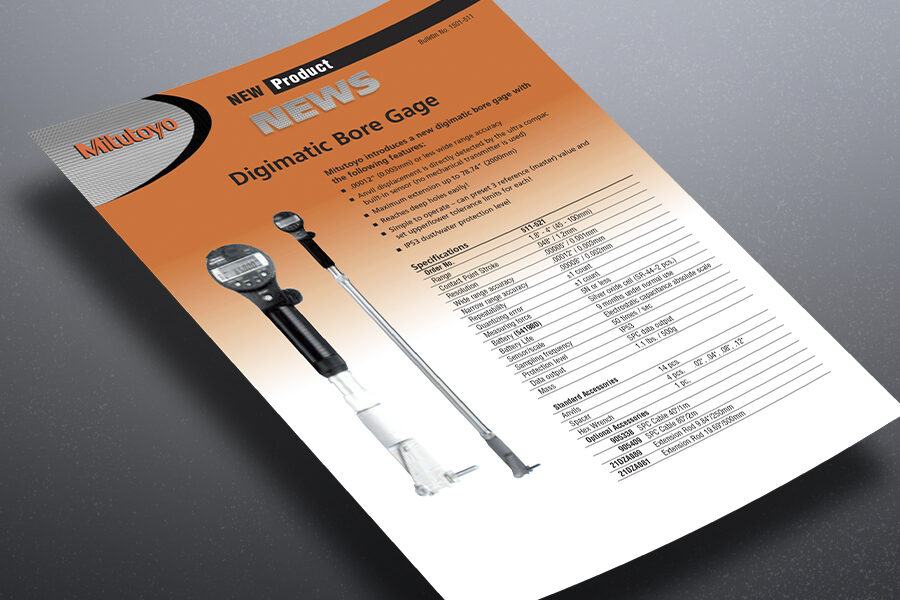

The simple-to-operate Digimatic® Bore Gage is exclusively designed to take ID measurements that are shown on a digital LCD display built into the instrument.

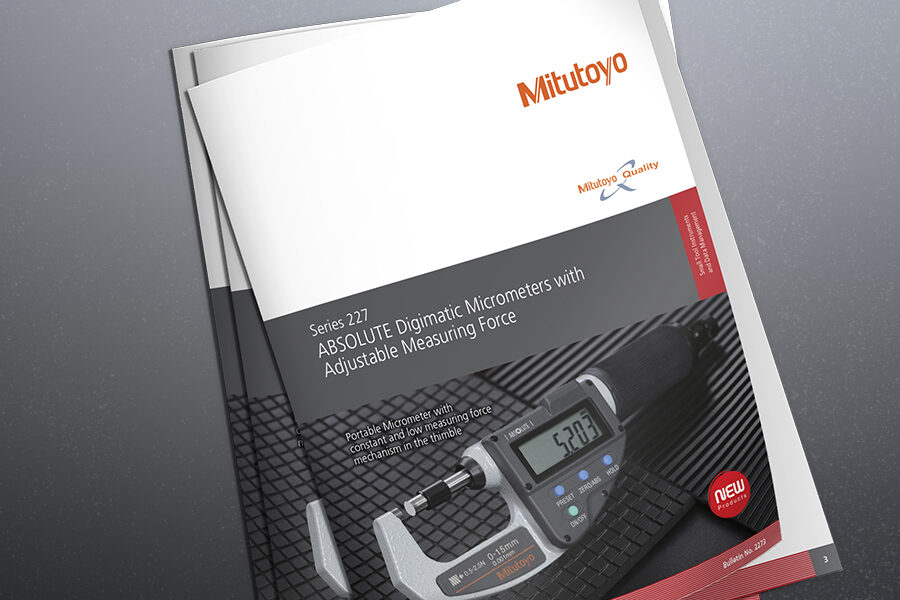

Portable Micrometer with constant and low measuring force mechanism in the thimble.

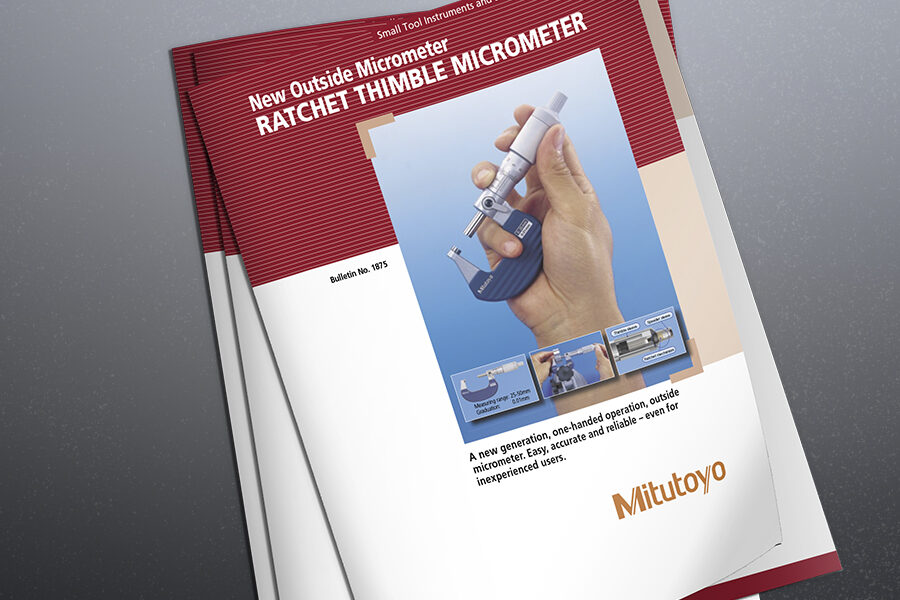

A new generation, one-handed operation, outside micrometer. Easy, accurate, and reliable – even for inexperienced users.

ABS coolant-proof caliper with dust/water protection conforming to IP67 Level. Can be used in workshop conditions exposed to coolant, water, dust or oil.

Inside/outside diameters, maximum/minimum heights, and displacement can be measured using a standard probe.

High-accuracy Holtest Series micrometers make three-point / two-point bore diameter measurements.

Equipped with “speed” enabling higher measurement efficiency, “operability” with automation and a wide variety of features, and expandability which offers upgrading to a complex system by incorporating optional detectors, this revolutionary measuring system defies conventional thinking.

All models are complete with Flat and VEE anvils, diamond and carbide ball indenters, and Rockwell blocks. The new frame design allows for a 7.1” specimen capacity.

Mitutoyo’s Linear Scale Systems tightly couple linear scale units with dedicated digital readout (DRO) units in order to accurately detect and display displacements for machine tools, measuring tables, 3D printers, XY tables, or any application requiring measured lengths or accurate...

The inherently non-contact measurement method of profile projectors makes this type of instrument highly suitable for measuring small parts that are unmeasurable with general-purpose contact instruments or plastic parts that are easily deformed.

DRO Retrofit Packages include all the components needed to accurately detect and display linear displacements on milling, grinding and lathe machines. Retrofit packages are available in many different sizes and types for 2- and 3-axes machines.

Designed for customers that manufacture and measure on a timed measurement schedule, Collection Scheduler works in conjunction with any Real-Time edition to alert operators when the next measurement is due with a colorful Andon display and timer.

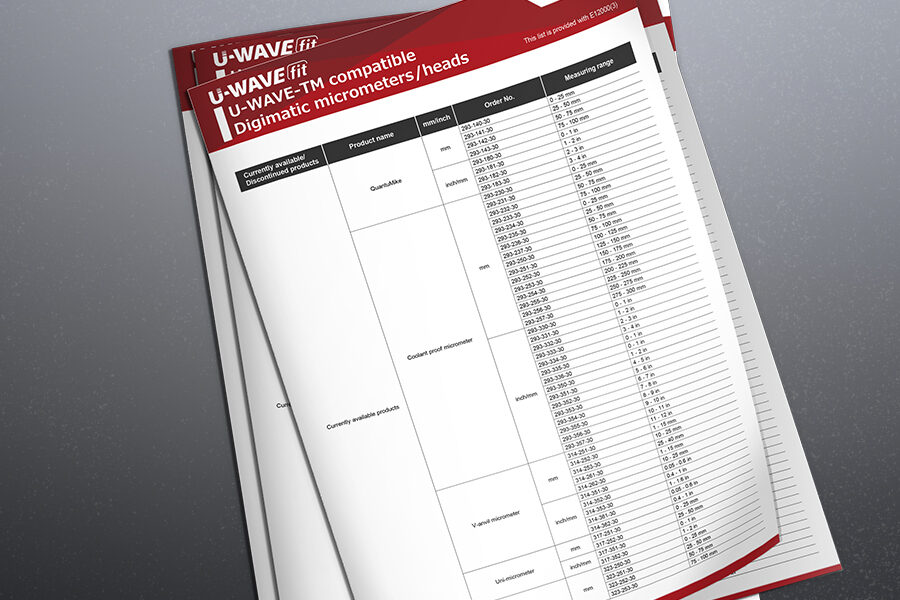

The new U-Wave Bluetooth transmitter utilizes a different wireless technology than the U-Wave and U-Wave Fit products. Please reach out to your local sales representative or www. mitutoyo.com for more information about any of these products.

MeasurLink® is Mitutoyo’s Data Collection and Real-Time Statistical Process Control Software. MeasurLink® can be used in any industry to manage inspection data collection and improve manufacturing processes.

Collect data quickly and easily with any of Mitutoyo’s Data Management products. Whether your need is to manage and retain incoming data, gather data from multiple tools to create a customer report, perform SPC, or simply send data into Excel,...

Must register on our end user portal to access this literature.

The CRYSTA-Apex V Series is a new generation CNC coordinate measuring machine that helps make the smart factory—a factory that leverages IoT for the advanced management of production and quality information—a reality.

The MiSTAR 555 Shop Floor CNC CMM is a highly environment-resistant Coordinate Measuring Machine, that allows shop-floor inspection outside the measuring room. With a user-friendly design that reduces the operator’s workload.

Height gages feature improved ease of operation and enhanced functionality.

With Mitutoyo Custom Solutions, you can customize Mitutoyo products and technology to meet the demanding needs of your specific application.

An educational guide to the basic technical information associated with a variety of Mitutoyo precision tools and instruments.

Outside micrometers are industry-standard measuring tools because of their high accuracy and resolution and ease of use.

A scant 500 thousand years ago, modern man (homosapiens) roamed the land. Today, their descendants use tools to build large structures, design high speed vehicles, and manufacture microscopic parts too small for the human eye to see.

Since the use of gauge blocks helps an organization to demonstrate traceability to national length standards, gauge blocks are in widespread use in corporations, universities, and laboratories throughout the world.

Mitutoyo America is also the first service organization to have A2LA Accredited Field Service Technicians. State-of-the-art M3 Solution Centers are geographically positioned to cover the United States.

It was during the 17th century when threads were utilised to measure the length of objects.

Mitutoyo’s unique ABS (Absolute) sensor automatically restores the last origin position when the indicator is turned on, allowing quickstart operation.

Simple, Easy-to-use Solar and Battery-powered Digimatic® Indicators.

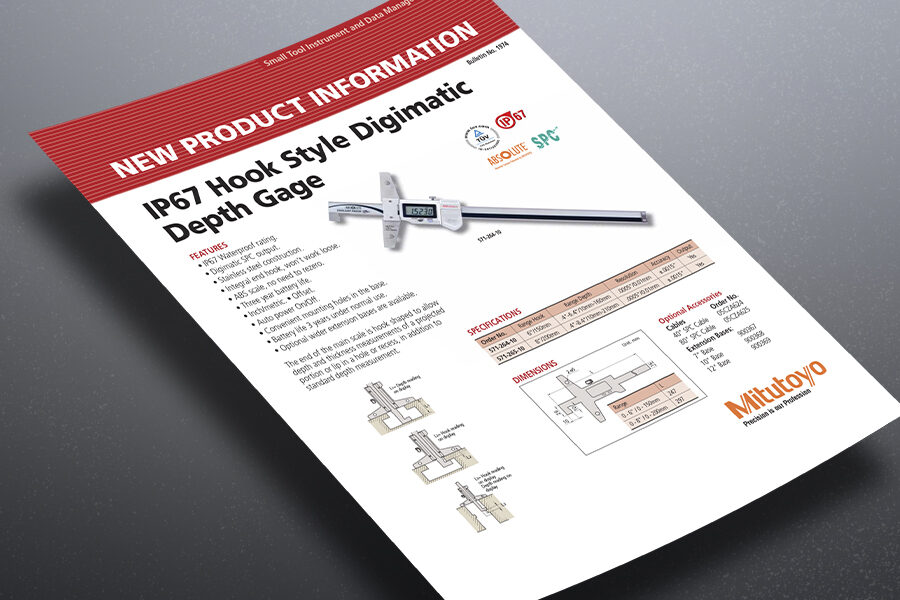

Specially designed to take depth and thickness measurements of a projection or lip in a hole or recess as well as standard depth measurements.

New model measures blind-hole diameter with high accuracy and high durability.

Best-selling range of bore gages now offers better accuracy, user-friendliness and durability.

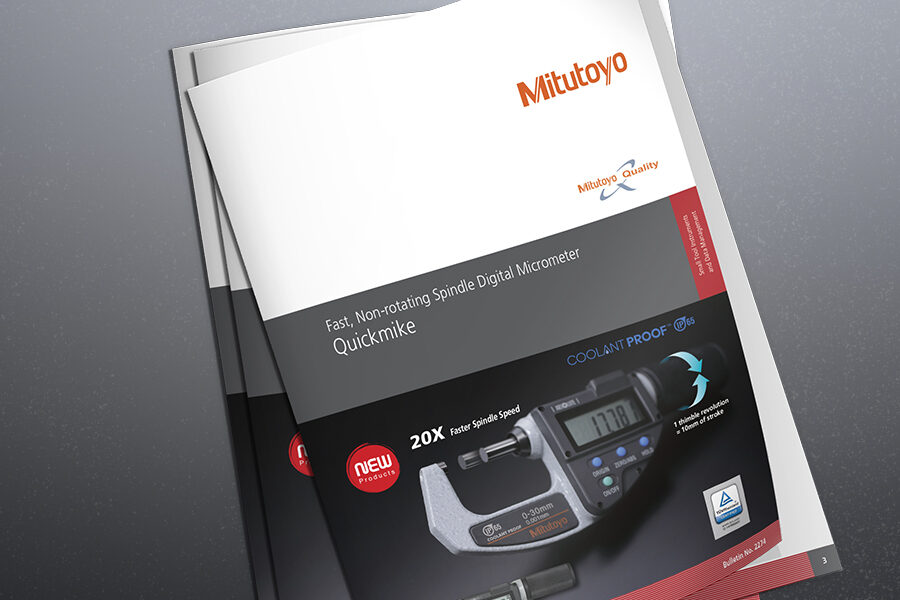

New, high-precision thread machining technology has made it possible to create a new thimble design incorporating a highly accurate screw with a pitch of 0.1mm. This is one-fifth of the conventional micrometer pitch of 0.5mm and provides a feed of...

Delivering ±0.5 μm accuracy at 0.1 μm resolution means Mitutoyo’s MDH25MB is the most accurate hand-held micrometer available*, and this instrument will enable you to easily and rapidly measure workpieces that require very-high-accuracy measurement.

Twice as Long Battery Life as before and Drastic Improvement in Measurement Efficiency.

Equipped with the electromagnetic induction type absolute encoder and AOS (Advanced Onsite Sensor) applied for ABS coolant-proof calipers.

In addition to standard types of micrometers, Mitutoyo provides a wide variety of micrometers dedicated to measuring specific and special applications.

For Calculation, Peak-Value Hold and Bore Gage Applications.

The ability of the indicator to track small changes in displacement deteriorates with prolonged use due to minute changes in clearance between the gears.

ZERO CERA BLOCK can also improve calibration work efficiency by eliminating the need for temperature compensation leaving only the thermally induced dimensional change of the calibration target to be considered.

Roundness/Cylindricity Measuring System combines world-class accuracy with superior maneuverability/ analytical capability.

Offering the highest precision level in its class, exceptional ease-of-use, and multifunction analysis capability.

A new PC-Compliant Roundness and Cylindrical-Form Measuring Instrument with extensive analysis features to enable measurement of a wide variety of workpieces.

Compact roundness tester equipped with a wide range of analysis features and capable of accommodating a variety of workpieces.

A new PC-Compliant Roundness and Cylindrical-Form Measuring Instrument with extensive analysis features to enable measurement of a wide variety of workpieces.

Remarkable operability and functionality revolutionize contour measuring systems and enable measurement that is fast, accurate, and easy.

Mitutoyo offers a wide range of form measuring equipment to make accurate, reliable surface roughness, roundness and contour measurements for nearly any application.

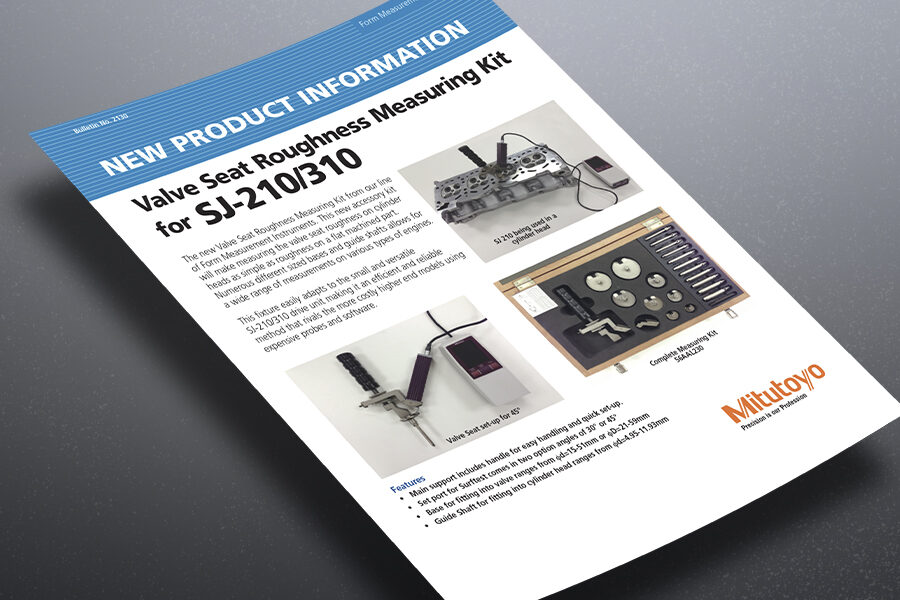

Numerous different sized bases and guide shafts allows for a wide range of measurements on various types of engines.

FORMTRACEPAK functions offer total support for measurement system control, surface roughness analysis, contour analysis, contour tolerancing, and inspection report creation.

Double performance in one system: combined contour and surface measurement machine delivers high accuracy, high speed, and simplified CNC measurement.

Surface roughness testers offer benchtop or portable operation and the choice of data analysis by PC or an easy-to-use dedicated processor.

The Surftest SJ-410 Series is a portable surface roughness measurement instrument with a user-friendly color-graphic LCD touch screen and takes measurements with the push of a single button.

The Surftest SJ-310 is a compact, portable, easy-to-use surface roughness measurement instrument equipped with extensive measurement and analysis features.

The CNC FORMTRACER SV-C4500 features a dual-sided stylus and performs highly accurate surface roughness and form/contour measurements with one unit.

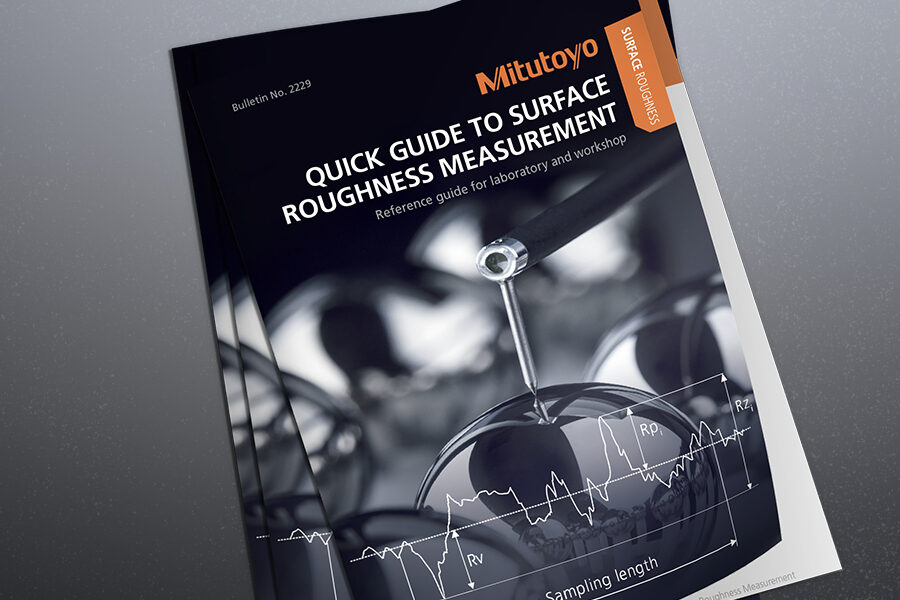

The roughness profile (R-profile) is the profile resulting from electronic highpass filtering of the primary profile with a cut-off wavelength λ c.

Ideal for measuring the thickness or height of a workpiece that can be easily affected by the measuring force.

Durometers are suitable for testing natural rubber, neoprene, polyesters, P.V.C., leather, thiokol, nitril, rubber, wax, vinyl, cellulose acetates, glass, polystyrol, and other materials.

HH-411 is a compact portable hardness tester that is user-friendly. A single touch of a button performs the non-destructive impact hardness test so it’s extremely easy to test workpieces on site.

Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics (A & B) and Light Force Brinell hardness testing.

The HM-200 series is ideal for quality control and mechanical characteristic evaluation using Vickers hardness testing of small areas.

The ergonomically designed FS70 high power microscope features extra long working distance plan objectives and is an ideal unit of a prober station for semiconductors.

Newly designed LED illuminators provide enhanced observation for higher accuracy and resolution.

Mitutoyo microscopes can be integrated into manufacturing systems, research and development equipment, and product inspection lines.

Optical data-processing system is what supports such a system configuration. In addition, “MeasurLink” offers the “Quality Control IoT that Mitutoyo advocates.”

The TAGLENS has ground-breaking ultra-deep focus, which allows completely in-focus images of the target to be captured instantaneously. This revolution in optical inspection will dramatically improve productivity and efficiency.

The LSM-6900 Series is an ultra-high accuracy non-contact laser-based measuring system mainly used for outside diameter measurements even on delicate or moving pieces.

Latest Generation of Absolute Assembly-Type Linear Scale. This scale leverages Mitutoyo’s unique electromagnetic induction technology to provide excellent resistance to oil, water, and other contaminants when compared with optical linear encoders.

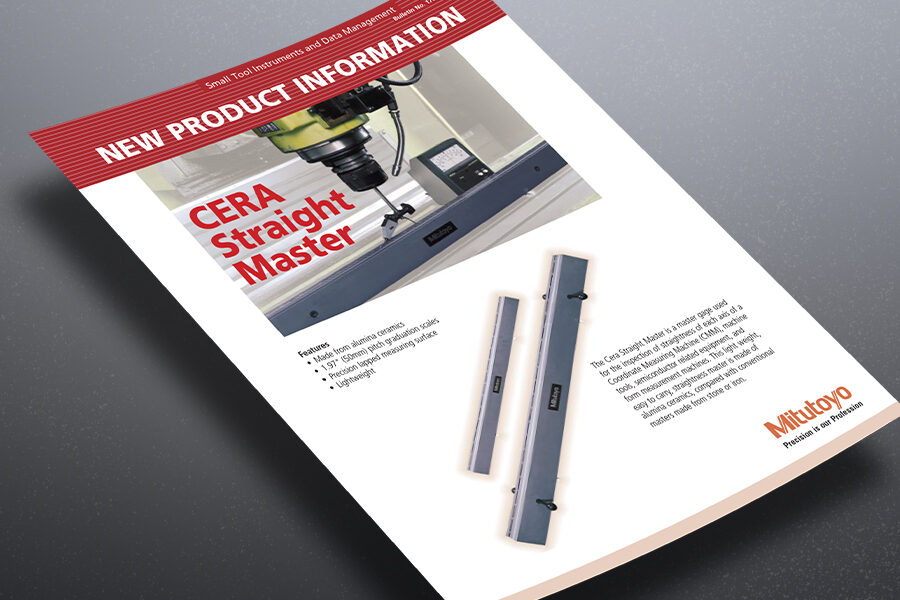

This lightweight, easy to carry, straightness master is made of alumina ceramics, compared with conventional masters made from stone or iron.

The Mitutoyo MF and MF-U measuring microscopes are available in manual and motorized units. Each model is packed with features, functions and high magnifications for highly accurate measurements on miniscule-sized parts.

Mitutoyo Selectable Resolution LVDT Probes and Displays Adaptable to Customer Demands Suited to a Wide Application Range from the Inspection Room to Building into a Production Line.

With the broadest scope of any commercial lab in the country, we can calibrate any type of measuring device or dimensional artifact — from small tools to surface finish specimens, gage blocks and step gages, to cylindrical squares and roundness...

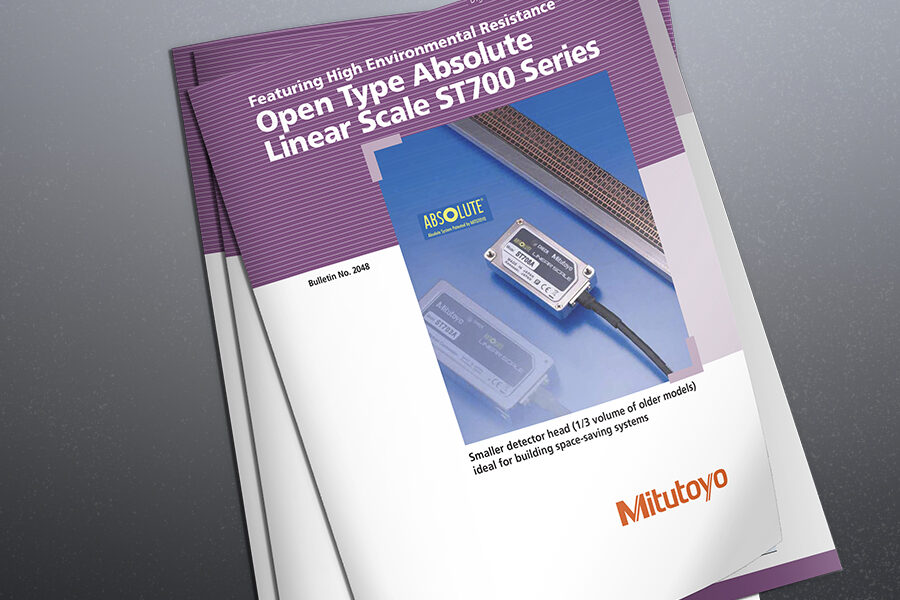

The ST700 Absolute Linear Scale uses features non-contact detection on exposed scales for precise linear positioning on a variety of different machine types.

Mitutoyo Digimatic Scales provides precise linear measurements and positioning. Digimatic Scale Units are available in horizontal and vertical mounting types for nearly any machine.

Highly accurate glass or metal-tape scales with ultra-compact detector head and an automatic signal-adjusting function for ease of installation.

The KA-200 Digital Counter shows displacements detected by linear scales. The KA-200 features high performance at a low cost with ABSOLUTE and incremental modes with 10 presets each.

The ABS AT1100 scale leverages Mitutoyo’s unique electromagnetic induction technology to provide excellent resistance to oil, water, and other contaminants when compared with optical linear encoders, thereby elevating the ABS AT1100 to the level of a highly reliable NC machine-tool...

The data logger function also allows storage of up to 1,000 pieces of data in memory, and batch transfer of stored data to an Excel-format inspection certificate, etc., by connecting to a PC with a USB cable.

The “U-WAVE” wireless communication system, collects measurement data in the inspection process swiftly and accurately, to increase a company’s competitiveness with detailed data analysis.

This document details how to select the right partner, hardware, and software needed to fit unique applications. Whether it is a single inspection station or a multiple facility installation, Mitutoyo offers the products and solutions to bring it all together.

MSURF has been updated to Version 5.0, making this dedicated point-cloud software for Mitutoyo’s SurfaceMeasure line-laser probe even more powerful by delivering productivity improvements to a wide range of applications. The software has various online/offline packages to provide the best...

By automatically adjusting the laser intensity and camera sensitivity for the environment and the workpiece material, the SurfaceMeasure achieves powderless measurement, providing a simpler laser-scanning environment.

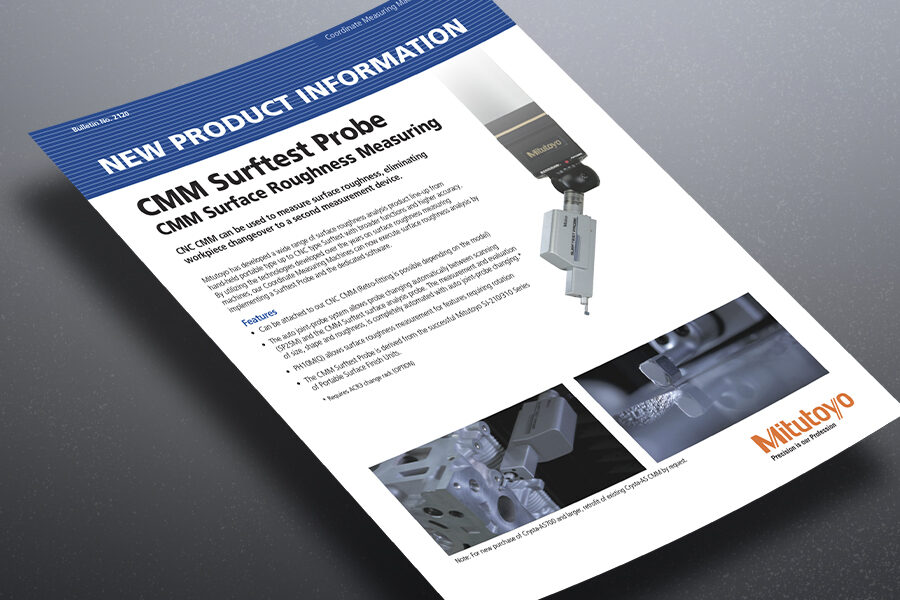

By utilizing the technologies developed over the years on surface roughness measuring machines, our Coordinate Measuring Machines can now execute surface roughness analysis by implementing a Surftest Probe and the dedicated software.

Mitutoyo offers many different CMM probe options, ranging from touch-trigger to non-contact probes as well as surftest probes and motorized probe heads to give manual and CNC CMMs more measurement versatility.

Based on our well-received standard coordinate measuring machine technology, we have developed, designed and manufactured coordinate measuring machines using various custom specifications in response to customer demands.

The automation of 3D coordinate measurement by introducing a CARB series system can allow simplification of conventional inspection/fixing jigs or even the elimination of inspection jigs and can achieve major cost reductions in addition to improving accuracy in parts and...

Production-line Coordinate Measuring System addressing today’s need for efficiency.

MiCAT Planner software by Mitutoyo generates CMM part programs with unprecedented efficiency. This drastically reduces programming efforts in developing part programs for coordinate measuring machines. The software’s automatic measuring program generator saves time while reducing costs.

High-performance, low-price CNC coordinate measuring machine meets global standards.

The CRYSTA-Apex EX Series has a 5-axis design that offers a choice of highly productive measurement methods, including “head touch” for point measurement by moving the probe head only in two axes, and high speed 5-axis touch trigger scanning.

The MACH Ko-ga-me is a fast, compact, lightweight, and easy-to-mount CMM and it is the ideal solution for automated cells. Mounted on any rigid frame, including machine tools, the MACH Ko-ga-me will provide CMM capabilities without the space requirements of...

SCANPAK provides high-performance scanning of work pieces and evaluation of profile callouts.

The CMM System Manager allows you to create a virtual representation of your CMM for simulation.

GEOPAK (Basic Geometry module) provides an easy graphical console to the operator by the use of toolbars and windows which can be personalized to the operator’s preference.

MCOSMOS allows integration among a series of applications, improving the efficiency of your CMM and the productivity of your quality control functions.

The Mitutoyo Styli and Accessories product line includes more than 600 probe components, as well as highly specialized equipment, to provide the best solution for your specific measurement needs.