Leveraging a catalog of over 8,500 products in tandem with non-Mitutoyo components, technology and software, we can provide custom solutions that seamlessly integrate your measurement systems with your production line and process.

CUSTOM SOLUTIONS, FROM START TO FINISH

CMM

With the flexibility to use the same technology on the shop floor as in the lab, a custom CMM solution can be integrated directly into your process, shorten inspection times and increase efficiency, helping to reduce scrap and increase profits.

Form

Whether it's surface finish, micro contours, thread inspection, roundness or other fine feature measurements, Form solutions can meet almost every need. With the addition of custom technologies, we help you maximize the efficient use of your quality measurement investment.

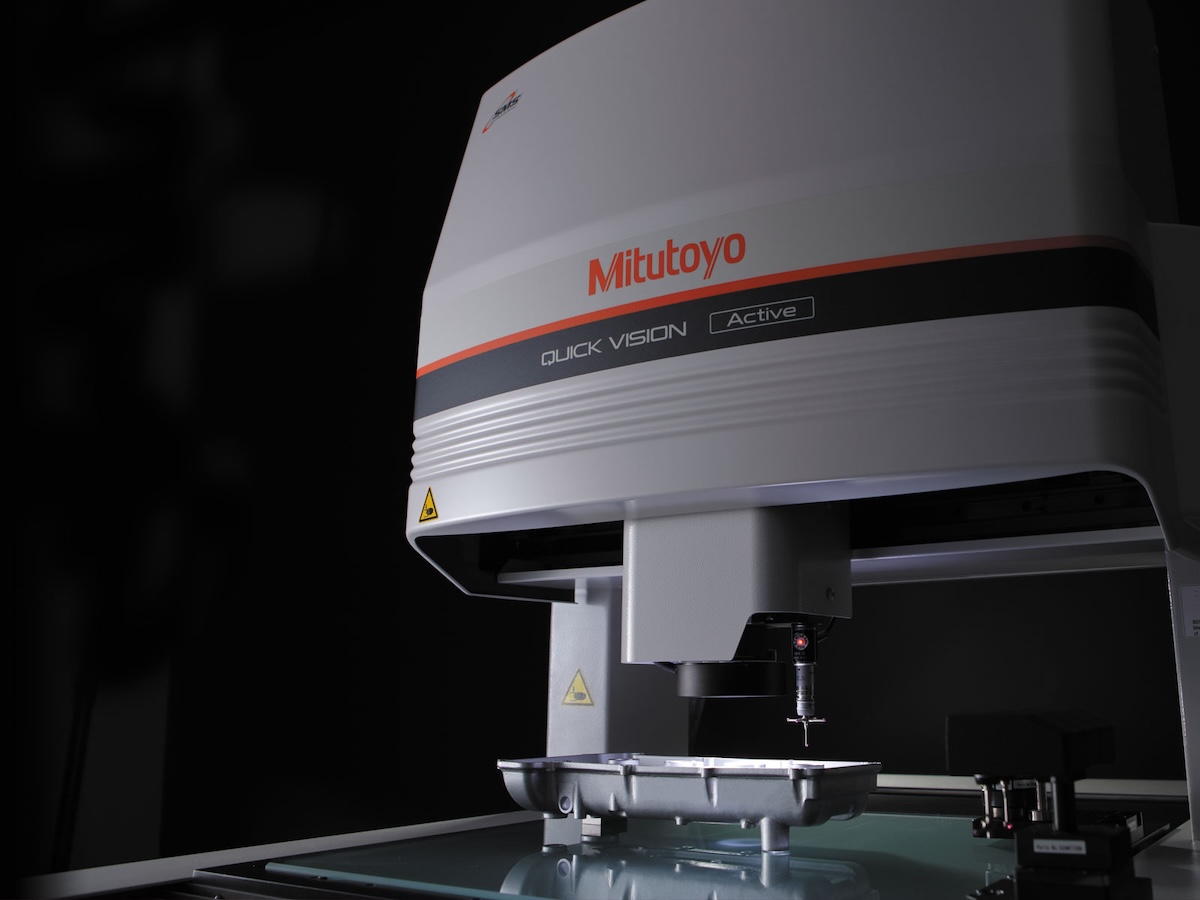

Vision

By using our CNC line of Vision machines, we can implement high-speed automated inspection of features too small to measure using conventional touch-probe technology. Additionally, additive features can be incorporated into your vision system, enhancing the mechanical, optical, electronic, firmware and/or software capabilities.

Major Instruments

Many of our other standard products can be customized and incorporated into an automated inspection process; including Optical Measurement, Sensor Systems, Hardness Testing Machines, Linear Encoders and DRO Systems, Small Tool Instruments and Data Management Solutions.

Our Process

Schedule a Custom Solutions Assessment

From customizing an existing product to developing completely new equipment, Mitutoyo can design, build and implement an inspection and measurement solution that perfectly fits your application. Schedule an in-person or virtual assessment with a Mitutoyo expert to discuss your unique needs.