From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

Find everything you need to make more informed decisions and advance your business, including Product Announcements, Articles, Case Studies, White Papers, Webinars, seminars and Videos, as well as our Knowledge Base, Mitutoyo Institute of Metrology and M3 Solution Centers.

88 Results - Clear filters

Access the complete Coordinate Measuring Machine Section L of the Mitutoyo US-100 Catalog

Measurement solutions for a wide range of fields in the semiconductor manufacturing industry, which is growing rapidly following a shift to production of electric vehicles, expansion of services in line with the implementation of 5G, etc.

Mitutoyo offers solutions to measurement of a wide variety of lenses from research and development to pre production and mass production.

Mitutoyo offers solutions to measurement of a wide variety of electric vehicles from research and development to pre production and mass production.

To help the thousands of operators using legacy CMMs, we are pleased to offer a U.S.-based trade-in program. When you trade in your current CMM and purchase a new Mitutoyo CNC CMM, you will receive the latest technology, ensuring reliable...

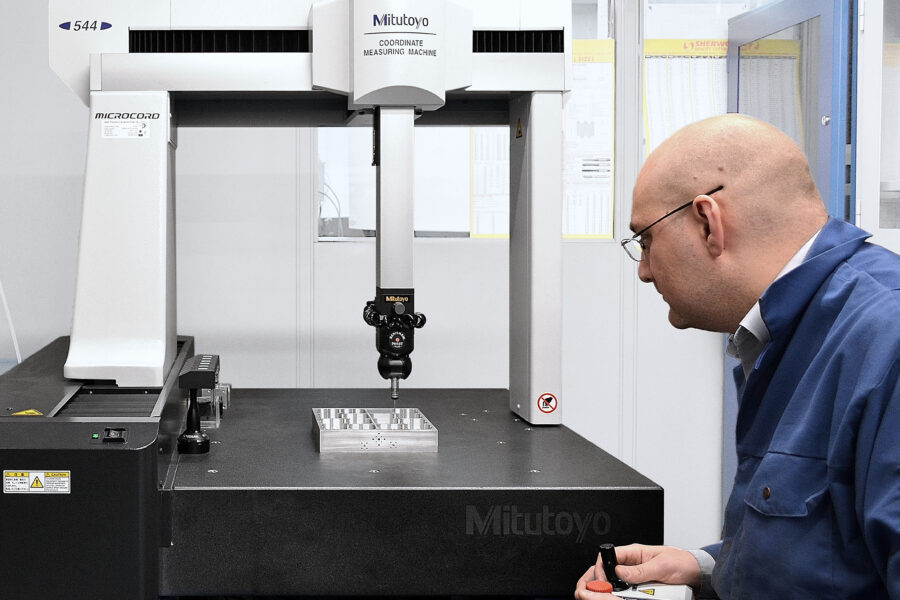

Industrial inspection and quality control rely on precision measuring machines and precision fixturing alike. Reliable and repeatable fixture set-up is a basic requirement for successful and accurate measurement. Mitutoyo fixtures: For measurably better results.

The best shop floor CMM just got better. Now with 5-axis measuring, allowing increased throughput with reduced calibration time. PH20’s unique ‘head touches’ allow measurement points to be taken by moving only the head rather than the CMM structure.

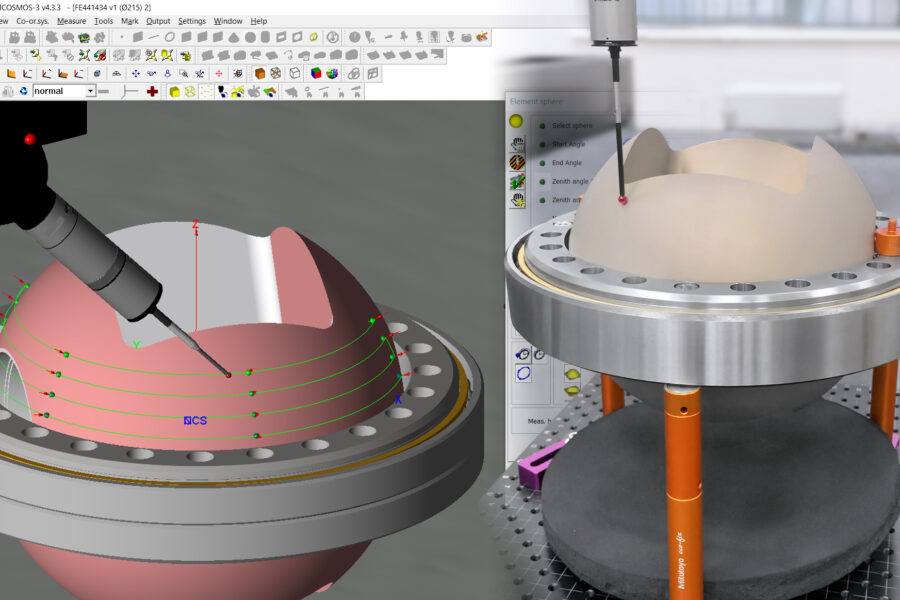

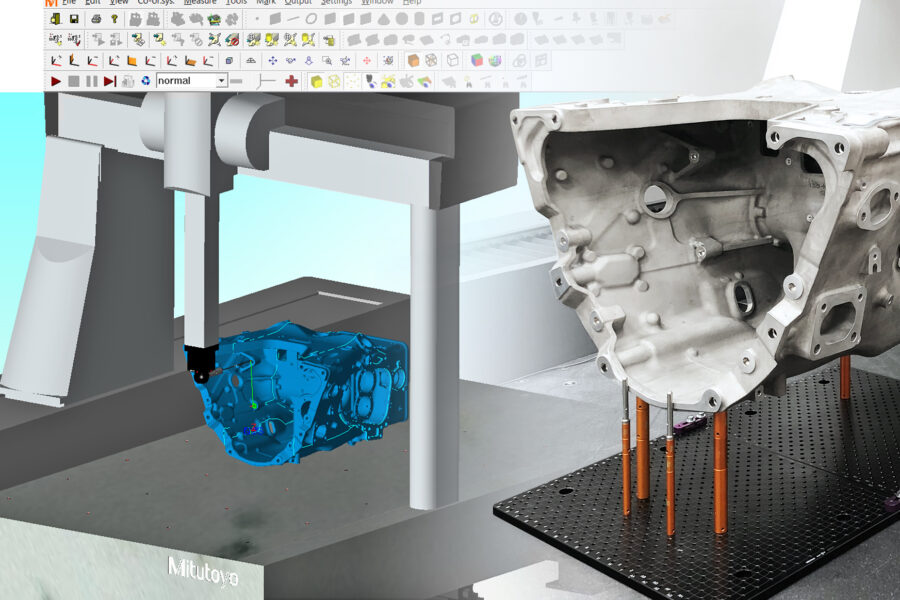

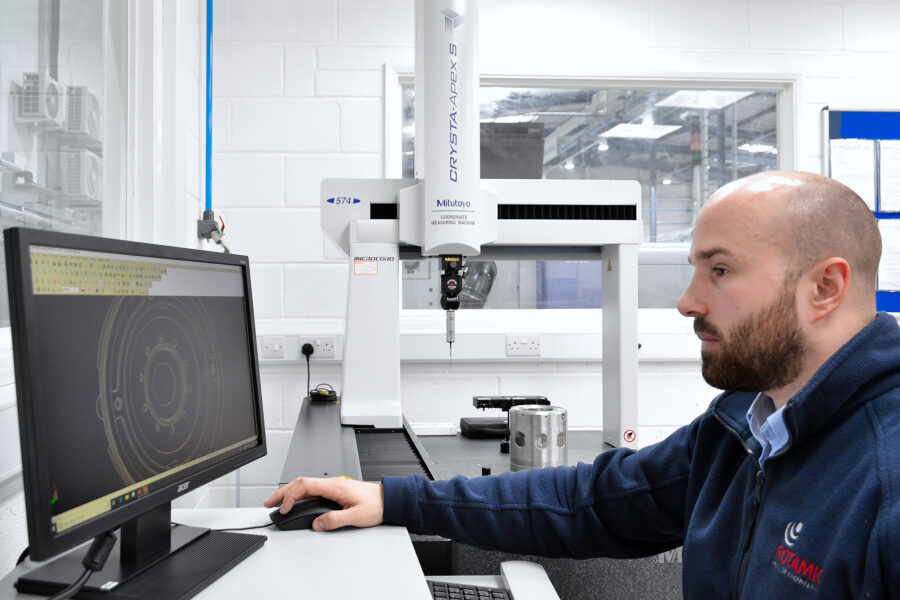

With MCOSMOS, your coordinate measuring machines become efficient information centers – powerhouses of design, production, and quality control. Streamlined measurements, as well as convenient and reliable data, are at your fingertips throughout the production process.

This literature is an educational guide to the basic technical information associated with a variety of Mitutoyo precision tools and instruments.

The Metrology Handbook 2nd edition is the most modern reference book available in the dimensional measurement and metrology field. This 280 page, full color book was written by Mitutoyo America’s own Nobuo Suga. The entire book is available for viewing...

As the world’s leading manufacturer of precision measuring equipment Mitutoyo offers a comprehensive variety of metrology products, ranging from the humble caliper to advanced vision measuring systems and 3D coordinate measuring machines. Now in its 40th year of operation, Mitutoyo...

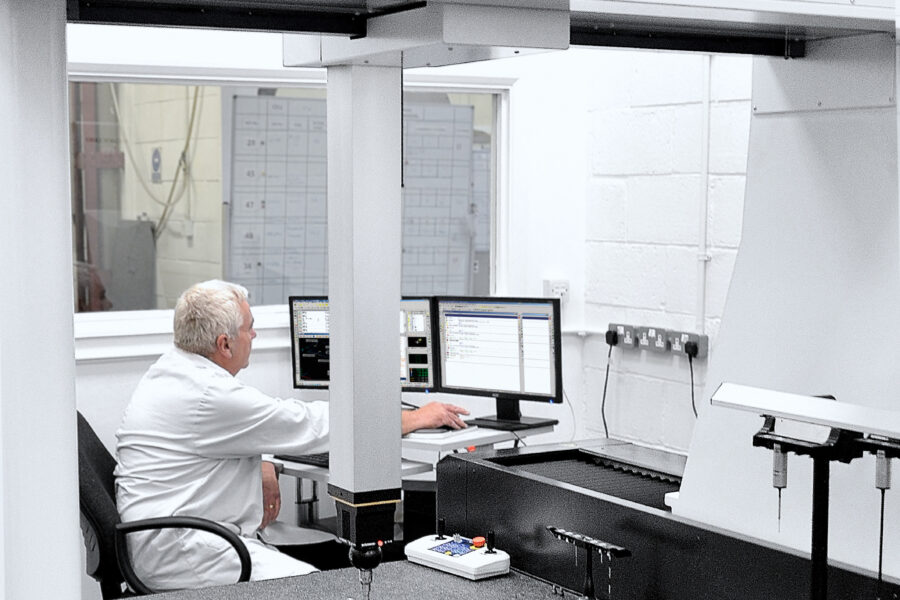

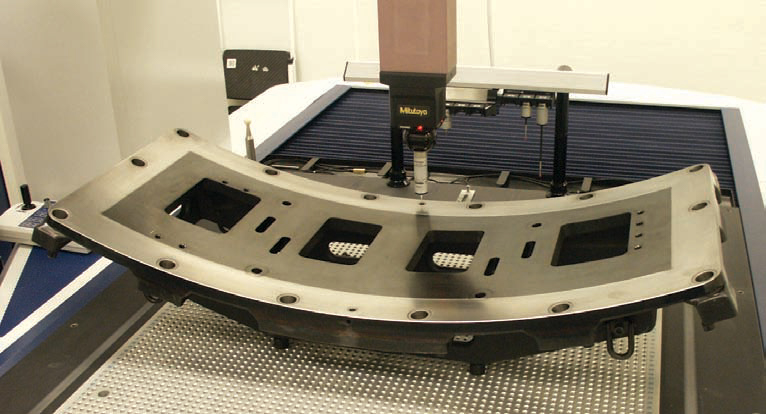

Xtrac is the World’s leading supplier of high-performance transmissions for top level professional Motorsport and High-Performance Automotive applications. Headquartered in Thatcham, Berkshire and with additional operations in the USA, Xtrac designs, manufactures and assembles all of its transmissions in-house using...

Must register on our end user portal to access this literature.

The CRYSTA-Apex V Series is a new generation CNC coordinate measuring machine that helps make the smart factory—a factory that leverages IoT for the advanced management of production and quality information—a reality.

The MiSTAR 555 Shop Floor CNC CMM is a highly environment-resistant Coordinate Measuring Machine, that allows shop-floor inspection outside the measuring room. With a user-friendly design that reduces the operator’s workload.

Muffett Gears can trace it origins back over 100 years. Remaining in Tunbridge Wells, Kent, the town it was established in, the business has grown into what is now a world-class manufacturer of precision gears and related components. The company...

Want to see what we’re up to at our very 1st “LIVE” Virtual Trade Show? Watch this short video and then check out our FREE Virtual Tradeshow at https://tradeshow.mitutoyo.com/.

This technical bulletin was developed to help owners of measuring equipment reduce risk and optimize their expenses in calibration. All measuring equipment requires calibration; however, there are many different types of calibrations which can lead to false assumptions and missed...

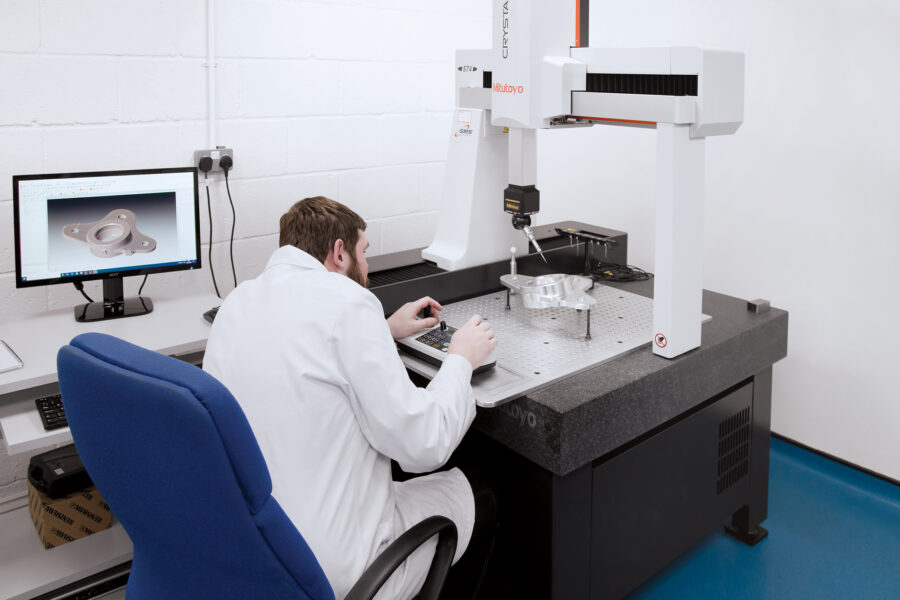

The new CRYSTA-Apex V Series from Mitutoyo, which delivers faster measurements without compromising the measuring machine’s inherent accuracy. It also supports measurement of workpieces of many different shapes, including impellers and blades. The CRYSTA-Apex V Series is a new generation...

As final inspection is usually the last process undertaken before manufactured components are dispatched, delays in this important activity can squander any time savings and efficiencies gained through the use of highly-productive CNC machine tools. Similarly, when performing in-process inspection...

Following the hi-profile launch of Mitutoyo’s CRYSTA-Apex V range of CNC Coordinate Measuring Machines (CMMs), the Basildon, Essex based ESL Group recently became the first company in Europe to take delivery of one of the advanced CM Ms. Founded in...

Hertford based Qualiturn Products Ltd a perfect example of the productivity increases that can be achieved by the application of advanced IT systems, the use of high-yield machine tools and the adoption of cutting-edge automation technology. In addition to performing...

Today’s manufactured components are more complex than ever, with more parts diversity, more model year changes and tighter tolerances than ever before. This is driving a need for increased quality control and the implementation of Geometric Dimensioning and Tolerancing (GD&T)...

Getting In-Line: Challenges and Benefits of Embedded Measurement: A Quality Magazine Webinar. In-line/near-line metrology measurement provides the potential for fast, flexible, efficient inspection that increases throughput without compromising quality. Shop floor CMM measurement however carries unique challenges and requires a...

First came smart people. They made machines. Over time, machines got smarter — and so did people. Today’s factory intelligence is the collaborative orchestration of people and machines. By blending intelligence from multiple sources, factories are truly becoming smarter. But...

With a complete range of in-line and near-line coordinate measuring machines — including the all new Mitutoyo shop floor CMM – MiSTAR 555 Series — Mitutoyo delivers exceptional durability, speed and accuracy for factory-floor applications of nearly any shape, size...

Based in Pendle in what has become known as Lancashire’s ‘Aerospace Valley’, Merc Aerospace is a renowned precision engineering company with over forty years of experience serving the aerospace industry. Specialising in the delivery of tight-tolerance components to demanding deadlines,...

Based in a purpose build 50,000 sq ft manufacturing facility in East Kilbride, Scotland, Quartztec Europe is the UK’s largest fabricator of quartz glass and one of the top five such companies in Europe. Quartztec Europe is a market leader...

Introducing the new MiSTAR 555 shop floor CNC CMM from Mitutoyo. Versatility. Simple Operation. Reduced Footprint Compact Design. Best-in-class Drive Speed & Acceleration. Widest Temperature Accuracy Guarantee for a Shop Floor CMM machine. Exceptional Contamination Resistance. With the new MiSTAR...

Currock Engineering Co. Ltd. is a major supplier of total solution packages to the global Aerospace sector and to several other equally demanding industries. Established in 1963 as a sub-contract machining and general engineering business, by 1995 the urgent need...

Introducing our Gold Care Program. Simply, it’s the packaging of select industry-leading CNC CMM’s with productivity-enhancing products and services. Each setup is valued at over $15,000. And, it’s bundled at our base machine’s price, helping you to improve your total...

The demand for fast and accurate inspection measurement continues to increase. Yet, achieving quality measurement programs takes time, and production cycles are often held up. To make matters worse, Different CMM programmers design model interpretations that influence or yield different...

“In the remanufacturing business, you can take apart a transmission, clean it, replace all the soft parts and get it back to the customer when they need a new part,” said Gary Noel, chief operating officer and member of the...

MSURF has been updated to Version 5.0, making this dedicated point-cloud software for Mitutoyo’s SurfaceMeasure line-laser probe even more powerful by delivering productivity improvements to a wide range of applications. The software has various online/offline packages to provide the best...

By automatically adjusting the laser intensity and camera sensitivity for the environment and the workpiece material, the SurfaceMeasure achieves powderless measurement, providing a simpler laser-scanning environment.

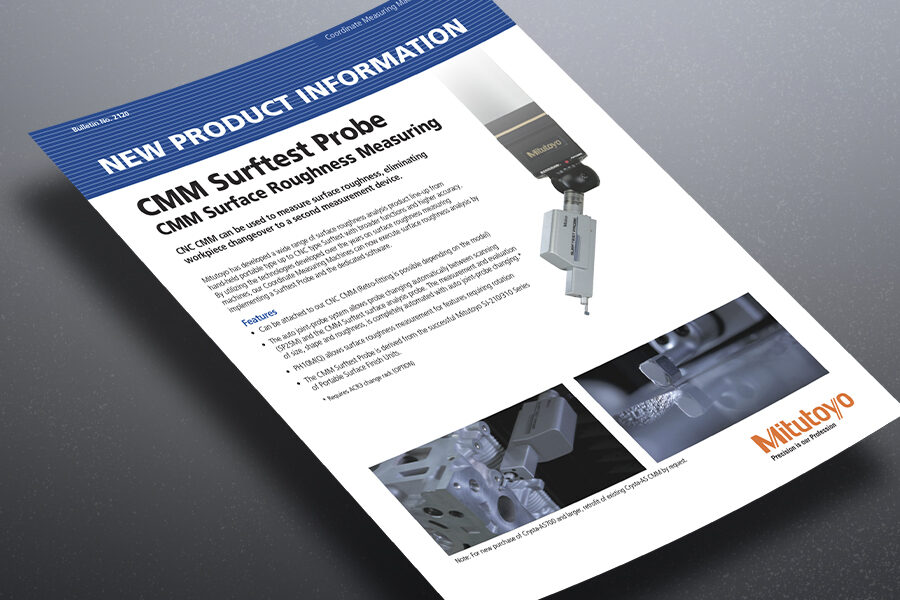

By utilizing the technologies developed over the years on surface roughness measuring machines, our Coordinate Measuring Machines can now execute surface roughness analysis by implementing a Surftest Probe and the dedicated software.

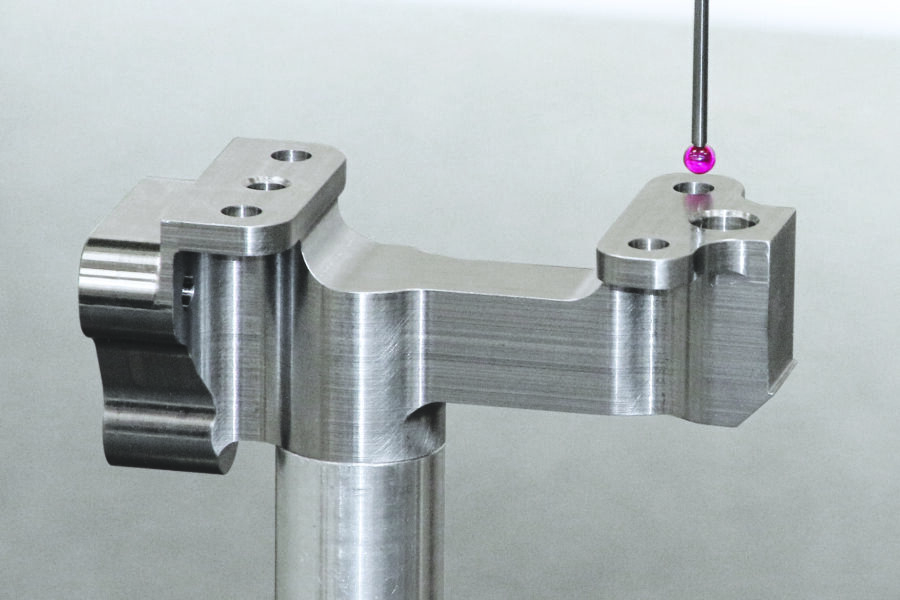

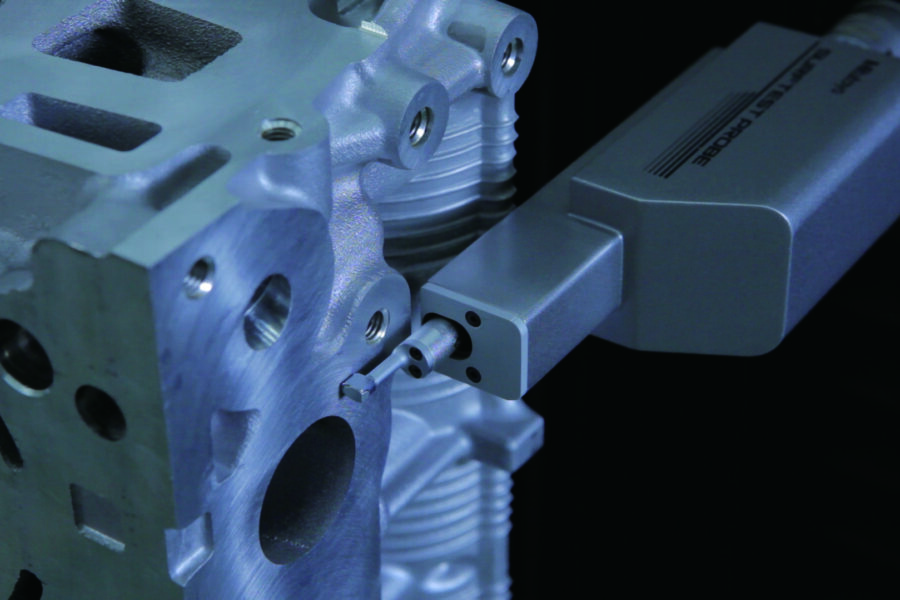

Mitutoyo offers many different CMM probe options, ranging from touch-trigger to non-contact probes as well as surftest probes and motorized probe heads to give manual and CNC CMMs more measurement versatility.

Based on our well-received standard coordinate measuring machine technology, we have developed, designed and manufactured coordinate measuring machines using various custom specifications in response to customer demands.

The automation of 3D coordinate measurement by introducing a CARB series system can allow simplification of conventional inspection/fixing jigs or even the elimination of inspection jigs and can achieve major cost reductions in addition to improving accuracy in parts and...

Production-line Coordinate Measuring System addressing today’s need for efficiency.

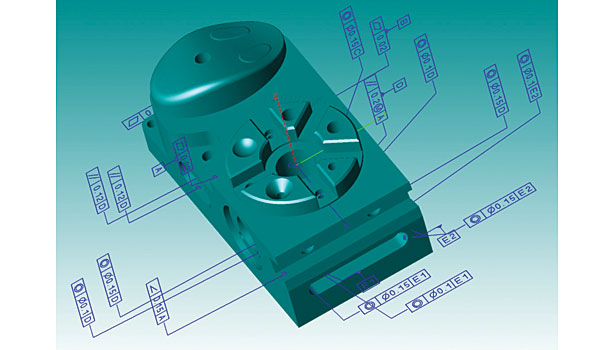

MiCAT Planner software by Mitutoyo generates CMM part programs with unprecedented efficiency. This drastically reduces programming efforts in developing part programs for coordinate measuring machines. The software’s automatic measuring program generator saves time while reducing costs.

High-performance, low-price CNC coordinate measuring machine meets global standards.

The CRYSTA-Apex EX Series has a 5-axis design that offers a choice of highly productive measurement methods, including “head touch” for point measurement by moving the probe head only in two axes, and high speed 5-axis touch trigger scanning.

The MACH Ko-ga-me is a fast, compact, lightweight, and easy-to-mount CMM and it is the ideal solution for automated cells. Mounted on any rigid frame, including machine tools, the MACH Ko-ga-me will provide CMM capabilities without the space requirements of...

SCANPAK provides high-performance scanning of work pieces and evaluation of profile callouts.

The CMM System Manager allows you to create a virtual representation of your CMM for simulation.

GEOPAK (Basic Geometry module) provides an easy graphical console to the operator by the use of toolbars and windows which can be personalized to the operator’s preference.

MCOSMOS allows integration among a series of applications, improving the efficiency of your CMM and the productivity of your quality control functions.

The Mitutoyo Styli and Accessories product line includes more than 600 probe components, as well as highly specialized equipment, to provide the best solution for your specific measurement needs.

Rather than acquiring manufacturing plant on a piecemeal basis, the practice of companies purchasing and using machine tools of various categories from single, preferred vendors is now firmly established. For example, milling machines of a particular brand would be used...

Over the past 40 years, Exeter, Devon based Rotamic Engineering Ltd has established an excellent reputation for the manufacturing of precision machined components. In addition to serving the demanding Defiance, Formula 1 and Medical industries, Rotamic has supplied customers in...

Nothing in the manufacturing industry epitomizes human safety more than the name Martin Baker. Founded in 1929 as an aircraft manufacturer that evolved to aviation ejector seats, the main entrance to the Uxbridge Company’s Headquarters has a large screen with...

Tewkesbury, Gloucestershire based Bushell and Meadows Ltd is a renowned subcontract manufacturer of high-quality, precision engineering components. The business has invested heavily in state-of-the-art, high-speed CNC machine tools and serves a range of demanding markets including the medical, aerospace and...

Based on a heritage site where Edwin Beard Budding invented the lawnmower in 1830 and the adjustable spanner in 1842, lmpcross Ltd is a manufacturer that continues this tradition; branding its business as a ‘world class centre of specialist precision...

Requirements for calibration appear in most national and international quality standards, and most organizations recognize that measuring equipment must be calibrated. However, there is much confusion regarding the definition of calibration, and this confusion increases quality-related risks to organizations. The...

This technical bulletin addresses how measurement accuracy and uncertainty can be accounted for when making statements of conformity to specified requirements (In/Out tolerances or Pass/Fail decisions.) In particular, this technical bulletin explores one simple rule called the simple acceptance and...

This technical bulletin addresses the accuracy and calibration of granite surface plates. The technical basis for this document is the American national standard (ANSI standard) entitled B89.3.7-2013, Granite Surface Plates. This technical bulletin summarizes key technical issues; however, the ASME...

The Ford Engineering Group is an award winning, family owned corporation specialising in the machining and pressing of components and assemblies for the aerospace, automotive and related high-technology industries. The Group, that can trace its origins back to 1910, is...

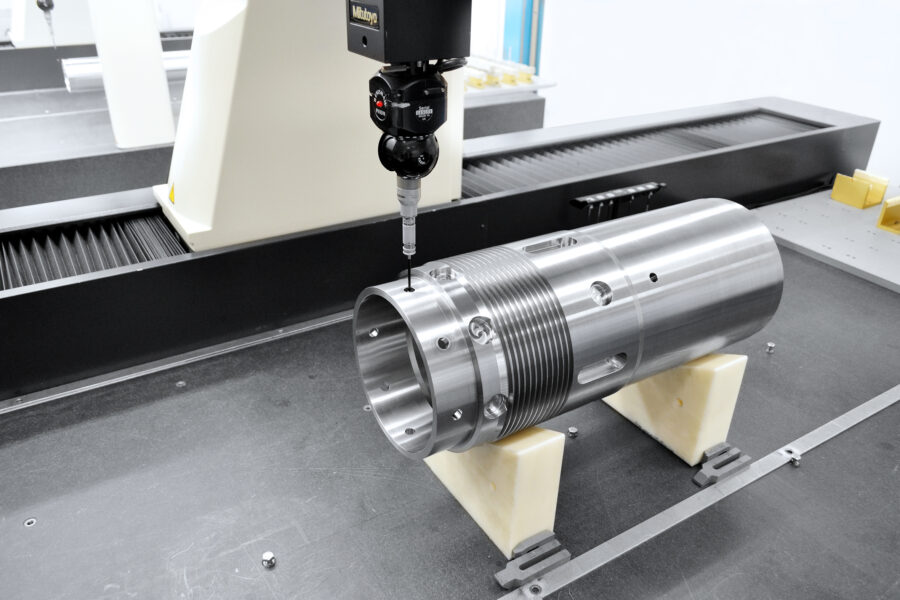

Over recent years, a wide range of advanced machine tools have been developed to help satisfy the global aerospace manufacturing industry’s requirement to produce parts faster than ever before. Although these innovative machines manufacture complex components within much faster cycle...

Now regarded as one of the UK’s leading subcontract engineering business, it is difficult to believe that North Shields based, Chirton Engineering Ltd was established as recently as 2003. From relatively modest beginnings, the company has enjoyed a meteoric rise...

Few companies involved in the manufacture of aero engine components can boast a heritage that stretches back to the dawn of the jet engine age. One such concern is JJ Churchill. Founded by Walter Churchill on Christmas Day 1937, Churchill...

Since STOBA Prazisionstechnik’s formation in Southern Germany more than 50 years ago the company has grown into a multinational concern, currently employing some 650 workers in four high-tech manufacturing plants located in southern Germany; Yantai in China and Small Dole,...

Ranked as one of the world’s top 100 new universities in the respected ‘Times Higher Education Rankings 2017’, Portsmouth University has rapidly ascended the UK academic rankings. This is credit to an £150m+ investment over the last ten years in...

Widely recognised as the world leader in the design and manufacture of transmission and drive train technology, Xtrac has built its business and reputation on a passion for innovation, precision and quality. So, when the company needed a metrology supplier...

When CDK Seals won an order for the production of metal components from a new aerospace customer, the leading manufacturer of seals for the food, pharmaceutical and petrochemical sectors had to employ new production equipment and methods. Historically, the Yeovil...

Located in a purpose-built manufacturing facility close to the M1 in Northamptonshire, Salcey Precision Engineering has earned a reputation for being able to undertake the more difficult precision machining work that is shunned by less able businesses. Salcey enjoys enduring...

Lancashire based Orthoplastics Ltd is recognised throughout the world as the global leader in the development and supply of both implantable grade plastics and biocompatible plastics for instrument applications. The company produces the highest quality, premium grade UHMWPE (Ultra-high-molecular-weight polyethylene)...

This technical bulletin addresses the accuracy and calibration of profile projectors, also known as optical comparators. No international or American national standard currently exists that addresses the specification of profile projectors. The technical basis for this document is the Japanese...

The quality, reliability and longevity of manufactured products is continuously improving, in addition to enhanced design techniques and developments in material science, this progress is largely due to the use of advanced quality control methods and equipment and the application...

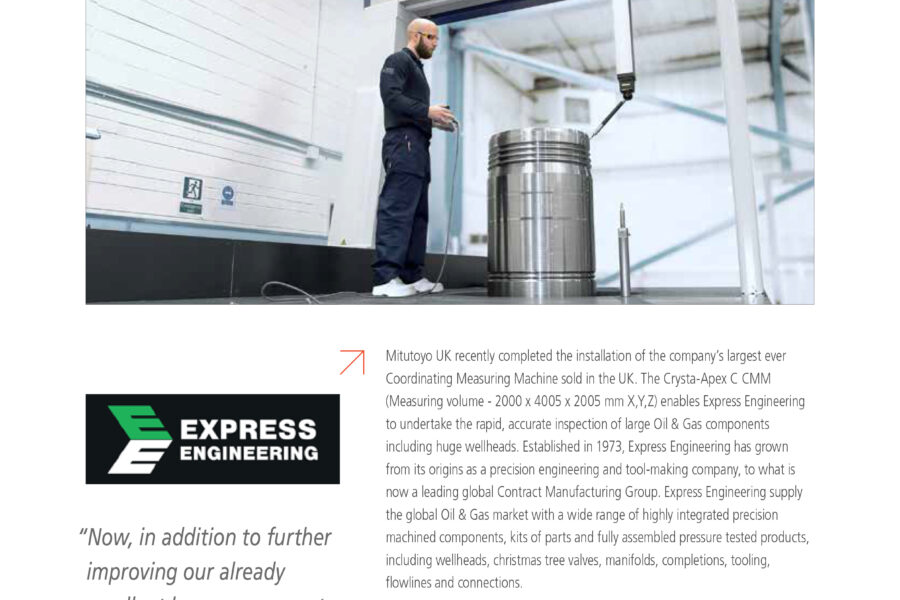

Mitutoyo UK recently completed the installation of the company’s largest ever coordinating measuring machine (CMM) sold in the UK. The Crysta-Apex C CMM, with a measuring volume of 2,000 mm x 4,005 mm x 2,005 mm, enables Express Engineering to...

This technical bulletin addresses an important aspect of the language of measurement – the units applied when reporting or discussing measured values

The global aerospace manufacturing industry is renowned for administering the highest standards of quality control and for utilizing detailed inspection and testing systems. The employment of skilled staff, the use of the best available inspection and testing equipment plus the...

Ultra-precise dimensional measurements critical to risk mitigation under AS9100 Rev. C. Gear Manufacturing, Inc. (GMI), Anaheim, CA, was founded in 1989 with a mission to manufacture high-quality custom gears and gear-related components and assemblies. Housed in 27,500-square-foot facilities, the company...

Gear inspection has long been considered a highly specialized, expensive and difficult part of the gear manufacturing process, requiring a wide variety of complicated gages, testers, dedicated CNC equipment and highly trained experts

FT Gearing buy Mitutoyo measuring and scanning technology.

During the past 25 years, coordinate measuring machine (CMM) sensor technology has expanded from tactile and scanning systems to now include optical, laser and surface finish sensors, effectively expanding the CMM’s capabilities. While each CMM sensor technology has its own...

More than a decade ago Waters Corporation, the scientific laboratory instrument and software manufacturer, started introducing high-end metrology equipment to its several sites in the South Manchester area to help cope with the increasing demands of advanced product development and...

In this webinar, we will introduce the MiCAT Planner automatic measurement program generation software that uses 3D CAD models and Product and Manufacturing Information (PMI) to enable one-click automated generation of measurement programs. With this new program, a complex program...

In this webinar, we will be introducing the MiCAT Planner automatic measurement program generation software that uses 3D CAD models and Product and Manufacturing Information (PMI) to enable one-click automated generation of measurement programs. With this new program, a complex...

Looking for speed and accuracy for its unique processes, an automotive supplier incorporates a surface finish probe in a CMM to obtain dimensions and surface testing in a single operation.

While manufacturers have applied model-based definition to product definition for some time, they have only recently applied it as a quality assurance process.

Mitutoyo’s Gold Care Limited Edition Productivity Program – Support and Service.

Gold Care is Back by Popular Demand. Your ultra-precise part inspection process demands the best. But the cost of ownership issues drives a strong bottom line focus as well. Our Gold Care Program lets you achieve both. Simply it’s the...

Mitutoyo has a wide variety of near-line and in-line gage technologies developed for the shop floor. Here we see one of the latest innovations in our Mach line of CMM’s the MACH Ko-Ga-Me.

Product demonstration of the new Mitutoyo America MACH Ko-ga-me CMM.

The Interface Assessment Division, a unit of the Naval Surface Warfare Center (NSWC) located in Corona, California, uses its precision measurement capabilities (traceable to national standards) to assure the form, fit and functional requirements of physical interchangeability and mechanical interoperability...