Peabody Mass., is home to a thriving hub of advanced manufacturing, where precision drives innovation. Mitutoyo proudly supports local industries with world-class metrology solutions designed to improve product quality and manufacturing performance.

Addressing Challenges in Peabody’s Precision Manufacturing Sector

Meeting the Demand for High-Speed, High-Accuracy Measurements

Manufacturers in Peabody, Mass., operate in highly competitive and precision-driven industries, including machining, defense, and electronics. These sectors require exceptionally tight tolerances, often within microns, to ensure that components fit and function correctly in final assemblies. Given the high stakes in these industries, whether it’s producing mission-critical aerospace parts, high-frequency electronic components, or precision-machined defense equipment, measurement accuracy is an absolute must.

However, precision alone isn’t enough. Manufacturers must also prioritize efficiency to maintain profitability and keep up with production demands. The challenge arises from the need to rapidly measure intricate components without sacrificing accuracy, as even minor deviations can lead to costly rework, scrap, or noncompliance with industry standards. With production lines running at high speeds, traditional measurement techniques may slow down workflows, and create bottlenecks in quality control processes.

Solution: Mitutoyo MDE-QuantuMike Micrometer

To overcome this, manufacturers must invest in advanced high-speed, high-accuracy measurement solutions that integrate seamlessly into their operations. Tools like the Mitutoyo MDE QuantuMike digital micrometer address this challenge with a spindle feed being up to four-times faster than conventional micrometers, enabling faster measurements, even on the production line, while maintaining exceptional precision. This allows machinists and quality control teams to measure more parts in less time, improving throughput without compromising quality.

By leveraging fast, repeatable, and highly accurate metrology solutions, Peabody manufacturers can enhance production efficiency, reduce inspection times, and maintain their competitive edge in precision manufacturing. These advancements support their ability to meet stringent industry requirements while optimizing workflows for greater productivity.

Key Benefits:

-

- Bidirectional Digimatic S1 Communication.

- Tolerance (GO/NG) icons on the LCD display for quick judgments.

- Displays tolerance judgement mark.

View the MDE-QuantuMike

Ensuring Compliance with Stringent Industry Standards

Peabody, Mass., is home to several aerospace and defense manufacturers responsible for producing critical components used in aircraft, military vehicles, navigation systems, and defense technologies. These industries operate under some of the strictest regulatory requirements, ensuring that every part meets exact specifications to guarantee safety, reliability, and performance. Even the smallest deviations from design parameters can lead to system failures, costly rework, or noncompliance with FAA (Federal Aviation Administration), DoD (Department of Defense), and AS9100 aerospace quality management standards, as well as the TAA (Trade Agreements Act) that is required for government contract work.

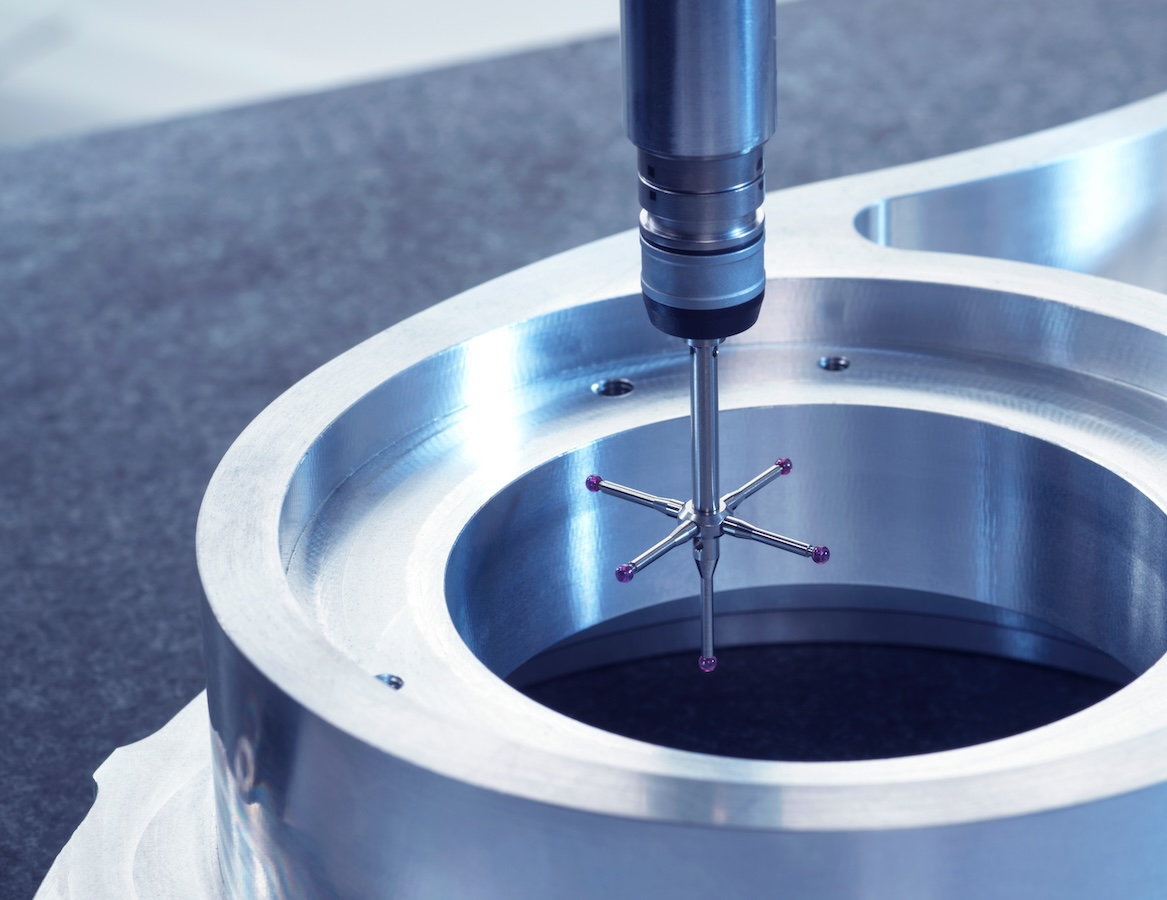

One of the key challenges aerospace and defense manufacturers face is the inspection of complex geometries in components such as turbine blades, engine casings, fuselage sections, and high-precision-machined parts. These parts often feature intricate designs, tight tolerances, and complex surface profiles that traditional measurement tools struggle to assess accurately. In addition, aerospace and defense parts must meet surface finish requirements to reduce friction, wear, and aerodynamic inefficiencies.

MiSTAR Series CNC CMM & SJ-220 Surftest: Solutions for Aerospace Production

The Mitutoyo MiSTAR shop floor CNC coordinate measuring machine (CMM) provides an ideal solution for the area’s aerospace industry by offering high-precision, automated measurements directly on the shop floor. Unlike traditional CMMs that require a controlled environment, the MiSTAR is designed to perform reliably in industrial conditions, reducing the need to transfer parts to a dedicated inspection room. Its automation capabilities minimize human error, improve measurement consistency, and accelerate the quality control process, helping manufacturers meet production schedules without sacrificing accuracy.

Additionally, for surface finish compliance, the Mitutoyo SJ-220 Surface Roughness Tester ensures that aerospace and defense components meet strict texture and finish specifications, preventing potential performance issues related to friction or material fatigue.

How the MiSTAR Series and SJ-220 Support Increased Aerospace Production Demands:

- Ensure compliance with AS9100, FAA, and DoD regulations

- Improve efficiency by reducing manual measurement time and human error

- Accurately measure complex geometries in high-precision parts

- Enhance quality control with shop-floor-ready, automated inspection solutions

With cutting-edge precision measurement technology, Peabody’s aerospace and defense manufacturers can streamline their quality control processes, maintain regulatory compliance, and confidently produce high-performance components that meet the industry’s highest standards.

see the full line of Mitutoyo CMM’sEnsuring Compliance in Peabody’s Medical Device Industry

Peabody, MA, is home to medical device manufacturers that produce critical components for surgical instruments, prosthetics, implantable devices, diagnostic equipment, and laboratory tools. These companies must adhere to strict regulatory standards set by the FDA (Food and Drug Administration), ISO 13485 (Medical Devices Quality Management System), and other global compliance organizations to ensure product safety, reliability, and performance.

Precision measurement plays a key role in quality control, as even the slightest deviation from specifications could compromise the functionality and safety of a medical device. One of the primary challenges in this industry is the inspection of intricate, small-scale components made from sensitive materials such as titanium, stainless steel, plastics, and bio-compatible ceramics. These components often have delicate structures, micro-sized features, and complex geometries, making them difficult to measure using traditional contact-based metrology tools.

Contact measurement methods, such as touch probes and calipers, may exert force on delicate parts, causing deformation or introducing inaccuracies. This is especially problematic for soft materials, flexible components, or devices with thin walls, micro-channels, or delicate coatings.

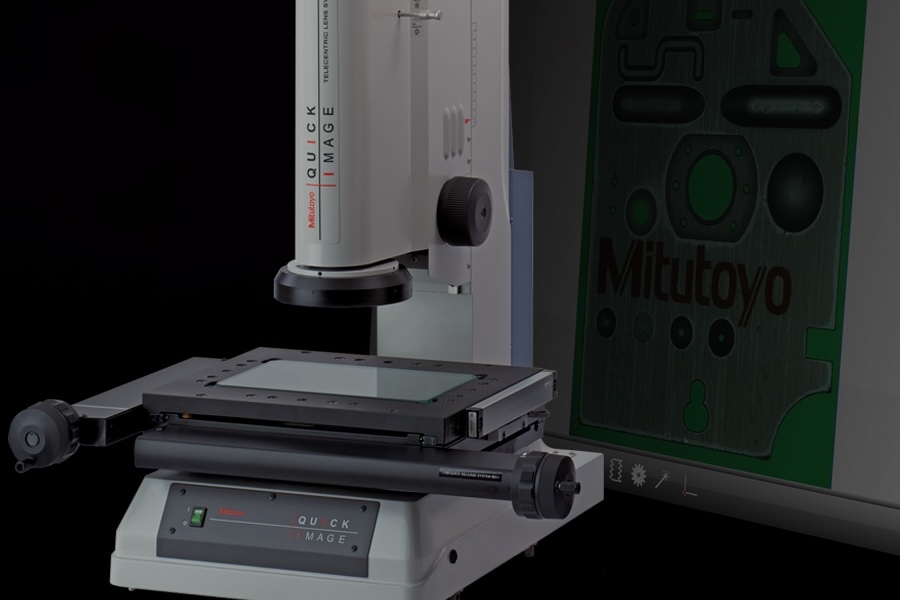

Solution: Quick Image with M3

The Mitutoyo Quick Image, known as QI, now paired with MetLogix M3 software provides a fast, highly accurate, and repeatable way to inspect intricate medical components without physical contact. This non-contact vision measurement system uses high-resolution optics and advanced image processing to capture precise measurements in seconds. With automatic edge detection, high-speed processing, and advanced data analysis tools, the Quick Image system ensures accurate, repeatable measurements while maintaining production efficiency.

By integrating the Mitutoyo QI with M3, medical device manufacturers in and around Peabody can enhance quality control, accelerate inspection processes, and ensure compliance with stringent regulatory standards. These cutting-edge metrology solutions provide the precision and reliability necessary to manufacture life-saving medical devices with absolute confidence.

View the M3 on QICase Studies in Precision Measurement

PLOTWORK: Improved production efficiency and measurement accuracy non-contact vision systems for intricate components.

KOHSEI PLANT: Achieved fully automated inspections, labor costs and improved precision, which led to increased productivity.

Take the Next Step with Mitutoyo

Enhance your manufacturing capabilities with Mitutoyo’s precision measurement solutions: