Mitutoyo America’s eLearning Courses are designed to give end-users unique, active learning experiences with tools and gages of all varieties. With these unique educational experiences, end-users can open the door to quality and extend the life of their tools with proper use, care, and replacement procedures. Courses are designed by our employees and certified through strict calibration practices and procedures, to combine accuracy and safety through all courses. These courses cover common practices, proper measurement procedures, and detailed operations for more experienced users. Digital versions of the tool are available for visual reference, but it is recommended to have the tool or gage available during the course.

Prerequisites:

N/A

Course Materials:

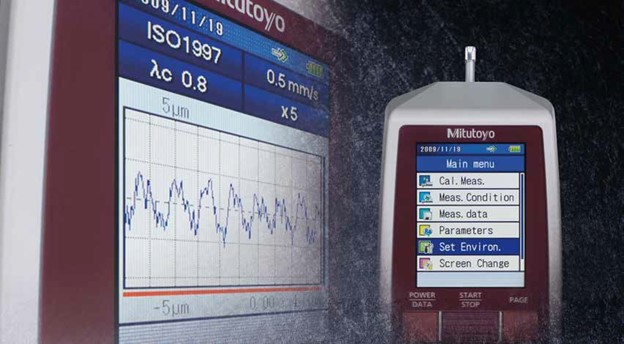

Startup Training for Mitutoyo’s SJ-210 Portable Surface Roughness Tester will help new users learn basic functionality of the gage. Start by being introduced to the gage, it’s components, and how to properly assemble the SJ-210. Details highlighting calibration, changing and applying measurement conditions, as well as taking sample measurements are covered in this eLearning Course.

The following topics are covered in this course:

1) Hardware Overview

Meet the SJ-210! Start with the standard accessories, assembly, and basic operation of the gage. Get detailed walkthroughs on how to assemble the unit for proper use, as well as details about each button (Power|Data, Start|Stop, Page, Function Buttons, etc.). After learning about the machine’s functionality, check the baseplate to learn about all the different ports and outputs available for the SJ.

Beyond the hardware introduction, learn basic machine operations such as Powering On and Off the gage, and how to retract and return the stylus. Before using the gage, you need to Set your Environment. Learn about the different options within this menu such as setting Date/Time, Designating Data Output source, Selecting Drive Unit, viewing files on your internal Memory Card, etc.

2) Calibration

Before using the SJ-210, users should calibrate their gage. Learn about the process for calibrating your SJ-210, and how to input the proper data for this process. Users will learn about the importance of calibrating the gage before it’s use.

3) Measurement Conditions

Learn about the different measuring conditions available on the SJ-210. Users will get a brief walkthrough on how to access the Measurement Conditions window, before a detailed walkthrough on the different types of measuring profiles, P (Primary), W (Waviness), and R (Roughness). Users can use this knowledge for a better understanding on what profile is necessary for their measurement trace.

Users can learn how the SJ-210 breaks down a trace taken by the unit, calculating results through the Measuring Conditions input by users prior to taking a trace, and displaying results on the screen.

To end the section, navigate the Measuring Conditions screen to learn more about the different submenus.

4) Parameter Setup

Users can learn more about the different parameters available on the SJ-210; from how to enable, tolerance, recalculate measured parameters, and more.

5) Data Output

The SJ-210 is outfitted with multiple output formats. View our walkthrough on how to enable, connect, and output data to your PC.

A certificate of completion will be awarded to the end-user for finishing the course/passing the proficiency exam following the conclusion of the course. Users have unlimited attempts at the exam.

PRICING

| Course | Standard Price |

|---|---|

| STF-210: Startup Training for SJ-210 | $40 |