From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

Find everything you need to make more informed decisions and advance your business, including Product Announcements, Articles, Case Studies, White Papers, Webinars, seminars and Videos, as well as our Knowledge Base, Mitutoyo Institute of Metrology and M3 Solution Centers.

180 Results - Clear filters

With its automatic angle correction function, the HH-V400 delivers reliable results wherever you work. Perfect for on-site metal testing, maintenance, and quality inspections. Key Features: • Portable rebound hardness testing • Vertical, horizontal, and 360° operation • Automatic angle correction...

Experience the next level of precision with the FTA-H3000, a powerful system that measures both contour and surface roughness in one trace. The new H-3000 Hybrid Detector allows fast, accurate measurements without changing detectors. Designed for speed, automation, and easy...

Make measurements simple. Place, click, and measure instantly. QM Fit’s Smart Vision System auto‑identifies parts and shows results in real time. Enjoy a compact design with a wide, comfortable field of view, a long‑focus lens, and an integrated computer. Trace...

Discover how the Mitutoyo TAGLENS with Pulsed Light Source (PLS) delivers ultra-fast focus—up to 70,000 focal changes per second. Capture multiple layers in perfect focus, create high-resolution 3D images, and unlock real-time depth visualization for your microscopy and inspection workflows....

Discover the Mitutoyo Surftest SJ-220 – a portable surface roughness tester designed like a hand tool for easy, on-site use. With a 2.8-inch intuitive touch panel, multiple drive unit options, and optional Bluetooth connectivity via U-WAVE-TIB, the SJ-220 brings precision...

Hungry for precision in food production? From donuts to data, Mitutoyo serves up precision measurement tools made for the food and beverage industry. Whether you’re slicing chips, scanning bread, or tracking quality with data, we’ve got the tech to make...

Introducing the new ID-C Digital Indicator! Control settings from your computer, enjoy a large display with max/min range, and perform tolerance functions with go/no-go judgment. Key features include a 330-degree rotatable display, function lock, and calibration warning. Enhance your measurements...

In this video, we take a deep dive into Mitutoyo’s commitment to quality. From micrometers to CMMs and vision machines, we explore how Mitutoyo’s dedication to precision and accuracy drives their innovation. Learn how Mitutoyo’s in-house development and manufacturing processes...

With multiple system configurations, enabling real-time measurement and data management, Mitutoyo is revolutionizing inline manufacturing with our high accuracy LG100, LG200 series, and the EJ Counter interfaces

Mitutoyo’s newly redesigned Quick Vision Pro Machines offer the next evolution in non-contact inspection. These new machines build on Mitutoyo’s tried and true Quick Vision platform and offer faster inspection with the same superb accuracies as previous models.

The RTX Roundtracer Extreme is a revolutionary all-in-one measuring system, providing highly accurate and efficient roundness, contour, surface roughness, twist, and 3D analysis on workpieces with various geometries in a single machine, saving time and improving productivity. Designed with a...

In this video, we’ll discuss the top 5 MeasurLink software tips you need to know for efficient data collection in your shop.

Learn how to use the security module in this MeasurLink training video to help protect your data.

Join us for our LIVE event “Hardness Testing Equipment Product Line-Up” streaming on YouTube & Facebook at 11am CDT! Make sure you are listening! When you hear Curtis say our secret phrase, text it to (281) 217-1864 for a chance...

The Mitutoyo Technology Solutions Group takes the well-established Points From Focus (PFF) technology to another level with a high-speed 3D imaging system. PFF is a 3D measurement technology which uses a stack of images in the focus direction to create...

Mitutoyo has long been a worldwide leader in precision measuring instruments and solutions. Because we are committed to helping you achieve 100% defect-free products, we used artificial intelligence to develop a simple method for the complex problem of defect detection....

The Mitutoyo RoboTAG is an optical measurement sensor designed to mount on robots and allows high-speed acquisition of images from multiple focal lengths. This new technology paves the way towards high-speed in-line inspection and optical measuring. Designed by the Mitutoyo...

Mitutoyo Quick Vision Systems are capable of accurate non-contact, high-throughput measurements. With QV3DCAD software, Mitutoyo Quick Vision Systems can be programmed from 3D solid models either at the machine, remotely, or completely offline.

The Resistance of Indentation Hardness Testing Forum Live Event presented by Mitutoyo America Corporation.

In our live Ultra Precision Laser Scan Micrometer Forum, Michal Grosenbach and Curtis Stubbs give hands-on demonstrations of the latest Mitutoyo LSM’s and how to overcome your dimensional challenges. They cover diameters, gaps, run-out, TIR and much more!

The FORMTRACER Avant Series form measurement system is a hybrid type surface texture metrology system that can measure both surface roughness and contour all within one system with high-accuracy and speed.

The new U-Wave Bluetooth wireless data collection transmitter utilizes a different wireless technology than the U-Wave and U-Wave Fit products. Benefits include: • No receiver required – Measurement data can be sent directly to a PC with Bluetooth®, Tablet or...

Want to see what we’re up to at our very 1st “LIVE” Virtual Trade Show? Watch this short video and then check out our FREE Virtual Tradeshow at https://tradeshow.mitutoyo.com/.

All of us at Mitutoyo America Corporation miss you, so we are inviting you to join us for our very 1st “LIVE” Virtual Trade Show. This event will give us the opportunity to gather together for 4 days to participate...

The new CRYSTA-Apex V Series from Mitutoyo, which delivers faster measurements without compromising the measuring machine’s inherent accuracy. It also supports measurement of workpieces of many different shapes, including impellers and blades. The CRYSTA-Apex V Series is a new generation...

Mitutoyo Vision Measuring Systems represent the most comprehensive lineup of vision systems in the metrology industry. Our vision measuring systems include cutting edge capabilities such as 0.25 micron accuracy, sub-pixel automatic edge detection, tracking autofocus, unparalleled focus capability, speed and...

Getting In-Line: Challenges and Benefits of Embedded Measurement: A Quality Magazine Webinar. In-line/near-line metrology measurement provides the potential for fast, flexible, efficient inspection that increases throughput without compromising quality. Shop floor CMM measurement however carries unique challenges and requires a...

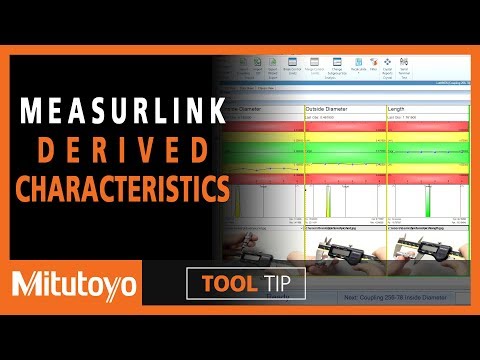

In this Mitutoyo MeasurLink video, we learn how to configure derived characteristics for automatic averages and more. This is a great feature for data collection and statistical process control. For more information on MeasurLink 9 and to download an evaluation...

With a complete range of in-line and near-line coordinate measuring machines — including the all new Mitutoyo shop floor CMM – MiSTAR 555 Series — Mitutoyo delivers exceptional durability, speed and accuracy for factory-floor applications of nearly any shape, size...

Modern smart manufacturing brings with it greater efficiency, increased productivity, data quality — and new challenges for collecting and analyzing the data management process. How can you achieve absolute precision in both production and reporting? And ensure compliance with industry...

Introducing the new MiSTAR 555 shop floor CNC CMM from Mitutoyo. Versatility. Simple Operation. Reduced Footprint Compact Design. Best-in-class Drive Speed & Acceleration. Widest Temperature Accuracy Guarantee for a Shop Floor CMM machine. Exceptional Contamination Resistance. With the new MiSTAR...

Mitutoyo Sheet Metal Micrometers are used to measure the thickness of sheet metal, paper, plastic, and rubber parts where a deep throat micrometer is required.

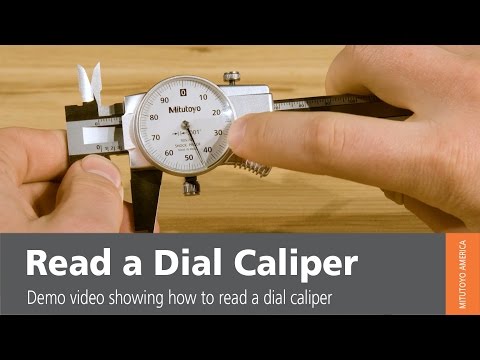

Mitutoyo America Corporation product demo video showing how to properly read a dial caliper.

Mitutoyo V-Anvil Micrometers are useful for measuring pitch diameters of taps which have a small diameter by using single-wire method. Measures the outside diameter of cutting heads with odd number of flutes such as taps, reamers and end mills.

The Disk Micrometer is designed to easily measure root tangent length of spur gears gears and measuring the thickness of sheet materials like paper, cardboard, rubber, and plastic.

The Mitutoyo Blade Micrometer’s anvil and the spindle have a blade for measuring the groove diameter of shafts, keyways, and other hard-to-reach areas.

Mitutoyo Caliper Type Micrometers have caliper type jaws making it easier to measure inside features with the accuracy of a micrometer.

The i-Checker is designed to calibrate a variety of indicators, including bore gages, Digimatic indicators, dial indicators, dial test indicators and linear gages.

Check Points for Measuring Instruments – This video covers the proper use of Digimatic Outside Micrometers from Mitutoyo.

Introducing our Gold Care Program. Simply, it’s the packaging of select industry-leading CNC CMM’s with productivity-enhancing products and services. Each setup is valued at over $15,000. And, it’s bundled at our base machine’s price, helping you to improve your total...

Mitutoyo’s vision product line represents the most comprehensive lineup of vision based metrology products in the world with cutting edge capabilities such as 0.25 micron accuracy, unique patented light adjustment tools, unparalleled focus capability, and new feature rich, easy to...

Mitutoyo America Corporation’s Lifting Lever installation instructional video.

In this video we discover how to use the Mitutoyo U-WAVE receiver as a virtual com port. The U-WAVE system enables easy wireless data collection from a measuring tool to a PC using the Digimatic protocol. Measurement workability is improved...

One of the newest features of Mitutoyo MeasurLink 9 is dynamic gauge which allows us to record readings from the gauge without actually taking them as a measurement value. MeasurLink 9 now allows for Max, Min and TIR data collection.

From precision gages to connection hardware and state-of-the-art software like MeasurLink® 9.0, Mitutoyo provides a full suite of precision metrology solutions for manufacturers. These solutions provide better smart factory integration, reliable wireless data collection and networked data management for faster...

Learn how to access the menu of a Mitutoyo MIG-4 measurement data transfer device, the multiplexer MIG-4USB and MIG-8USB convert digimatic data collection output measurements to ASCII text via USB or RS-232C and outputs it to an external data management...

The new U-Wave Fit wireless data management transmitter from Mitutoyo fits to the back of any Mitutoyo Digimatic hand-held metrology measuring instrument. This new design allows for a snug fit behind the display resulting in a more ergonomic feel for...

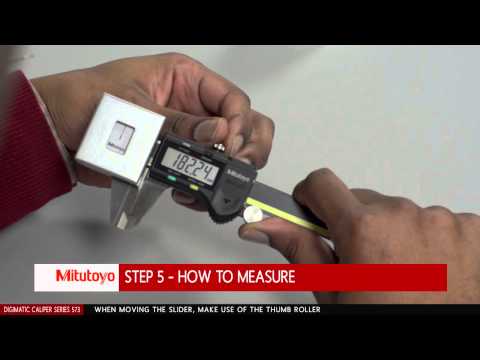

Mitutoyo product demo video showing the proper use of our digital calipers.

Our full range of roundness and cylindrical-form measuring instruments come with extensive analysis features that accommodates a wide variety of workpieces. Our PC based Roundtest products incorporate accessible Roundpak software with patented continuous internal/external diameter measurement reducing the need to...

The demand for fast and accurate inspection measurement continues to increase. Yet, achieving quality measurement programs takes time, and production cycles are often held up. To make matters worse, Different CMM programmers design model interpretations that influence or yield different...

Our Quick Vision ACTIVE Series CNC Vision Measuring System offers an automated vision measurement system featuring a space saving ergonomic design all while delivering high-speeds, high-accuracy and high-throughput.

From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

In this episode of the Metrology Training Lab , we’re going to revisit the calibration of calipers and look at a specific issue with dial caliper calibration.

Manufacturing companies across every industry want to improve the quality of their products while keeping their operating costs low. Mitutoyo’s MeasurLink is the ideal software to assist companies with achieving these goals. As a Data Collection and Statistical Process Control...

In episode #021 of Mitutoyo’s Tool Tip video series, we discover how to use the semi-float option of the LH-600 Digital Height Gauge. The semi-float feature allows for precision measurement of the height gauge while moving. This is a time...

In this episode, we’re going to discuss the calibration of the high accuracy Mitutoyo MDH outside digital micrometer. In past episodes, we’ve discussed the general calibration of outside micrometers, but the MDH is more than twice as accurate as any...

In this height gauge tutorial, we will look at setting up a new Mitutoyo Linear Height Gauge. We will cover the height gauge calibration procedure, zero the scale, set the absolute origin and switch from lower to upper probe positions.

In episode 012 of the Metrology Training Lab, we’ll explain the accuracy and micrometer calibration of mechanical outside micrometers. You may be surprised to find out the accuracy of a mechanical micrometer with a graduation of 0.001” is one-tenth of...

Learn 4 tips that will help make your Mitutoyo KA-200 digital readout more productive. The KA-200 Counter is a great DRO for machine shop Bridgeport or any other milling machine or lathe.

In episode 11 of the Metrology Training Lab, we look at the influence of temperature measurement in the quality lab. All materials grow and shrink as the temperature changes. You may think these changes are small, but every measurement is...

Catch a glimpse of what the future of metrology looks like, and how Mitutoyo has set itself up to play a key, innovative role in it. Mitutoyo America’s President Matt Dye explains the quick evolution of smart factories and smarter...

We’ve been teaching hands-on classroom courses in dimensional calibration for decades and in recent years we’ve developed some written theory tests along with performance tests to demonstrate skills. This had led to Mitutoyo America issuing the first and only certified...

In this episode we are going to talk about some quality rules that are often used in calibration to determine the acceptability of measurement standards or systems. For example, in a past episode of the metrology training lab we discussed...

In this episode, we want to recognize and appreciate a piece of measuring equipment that rarely get much glory but is the foundation for much of the work done in this business – the granite surface plate. The surface plate...

In today’s Tool Tip, we learn about the new Mitutoyo D2 Digimatic output system for SPC. The D2 system is compatible with U-Wave and MDH Micrometer from Mitutoyo.

In this episode of the Metrology Training Lab series by Mitutoyo, we learn how to calibrate gage blocks, stacking or wringing gauge blocks and a brief history. These simple little blocks are something special. Each one with their flat and...

In this episode, we’re going to talk about the how to calibrate calipers. In past Mitutoyo Metrology Training Lab episodes, we have defined the concept of calibration, discussed the purpose of calibration, and introduced important aspects of what makes a...

In today’s Tool Tip we look at the Mitutoyo Height Gage LH-600E and discover how easy it is to perform data output. The Linear Height LH-600E/EG Series 518 is a high performance 2D measurement system for use in calibration and...

In Episode 6 of the Mitutoyo Metrology Training Lab series, we look at how to calibrate outside micrometers. Calibration is a search for errors and we want to develop a calibration method that efficiently hunts down and finds any potential...

When it comes to Mitutoyo’s second generation of Test Indicators, there really is no comparison, and Mitutoyo’s small tools product support specialist, Mike Grosenbach, demonstrates four reasons why the new Mitutoyo Dial Test Indicators are the best in the metrology...

In this metrology training episode, we are going to teach you how to speak like a measurement professional. We are often dealing with small numbers in this business – tolerances – errors – deviations – uncertainties – most of the...

Mitutoyo Tool Tip Episode #015, learn how to capture the screen from the SJ-210 Surface Roughness Tester. The Surftest SJ-210- Series 178-Portable Surface Roughness Measurement Tester features a 2.4-inch color graphic LCD provides excellent readability and an intuitive display that...

In this episode of the Metrology Training Lab where we demonstrate how to calibrate, we are going to talk about requirements traceability, or sometimes called metrological traceability. Here’s the question that traceability and calibration answers – say I make a...

In this week’s Tool Tip, we look at the free surface finish measurement software from Mitutoyo. The Surftest SJ-201P, 210, 301, 310, 401, 402, 411, 412, 500, SV-2100 Metrology Communication program is a free surface roughness measurement software package. Please...

In episode 003 of the Metrology Training Lab, Dr. Jim Salsbury examines what makes a good calibration method. We look at five calibration methods developed by the American Society of Mechanical Engineers or ASME. The American National Standards covered in...

In this unboxing video, we look at the Mitutoyo 500-762-20 Digimatic Caliper the 6 inch coolant proof caliper. Features include IP67 Waterproof rating, hardened stainless steel construction, OD, ID, depth and step measurements, SPC output and fitted case.

Mitutoyo Tool Tip 013 Skidded VS Skidless – In this episode of Mitutoyo’s Tool Tip, we look at the difference between skidded and skidless surface roughness measurement. Surface roughness measurement or surface finish, can be measured using various metrology roughness...

In the second video of our Metrology Training Lab series, we continue our calibration training and address the following questions. 1. What does calibration mean? 2. What is the real purpose of calibration? 3. What makes a bunch of measurements...

Learn how to install the Mitutoyo wireless U-WAVE receiver for SPC data collection. This video is part of a series designed to be an installation and instruction guide for MeasurLink® SPC software and the Mitutoyo U-WAVE quality control wireless system....

Easy data management using the wireless Mitutoyo U-WAVE system. First, connect the U-WARE receiver to the PC, launch the U-WAVEPAK software, open your data collection software such as Microsoft Excel or other statistical process control software and finally start taking...

Learn how Mitutoyo MeasurLink works with DAQ sources. Use MeasurLink for data collection from USB wired and U-Wave wireless systems. Connect up to 1,600 metrology devices for SPC (statistical process control) using the U-Wave transmitter and receiver to PC software...

This week we find out what’s in the 543-342B Digimatic indicator box. The Mitutoyo 543-342B Digimatic indicators are for calculation applications. These metrology indicators allow the user to enter the appropriate formula factors for a fixture to the application. This...

Mitutoyo Type A & Type B SPC cables are used to output measurement data from IP67 digital calipers or micrometers with statistical process control output feature to the digimatic mini processor, digimatic display unit, multiplexer or other device. SPC Connecting...

In this video, we will demonstrate how to unpair the Mitutoyo U-WAVE Data Management Receiver. The U-WAVE SPC system enables easy wireless metrology data communication from a measuring tool to a PC using the Digimatic statistical process control protocol. Measurement...

Mitutoyo Unboxed Friday 005 – This week we look at the Mitutoyo MDH Micrometer and find out what’s in the box. The Mitutoyo 293-130-10 MDH High-Accuracy Sub-Micron Micrometer, as seen on Quality Digest, has a measuring range of 0-1″/0-25.4mm inch/metric.The...

This week we look at ways to reduce the misuse of your Digimatic® indicators. Learn how to lock out the inch/metric, TIR, min/max, preset and zero functions on Mitutoyo ID-C Indicators. ID-C Parameter Setting Software: https://www.mitutoyo.com/idcsoftware

The Mitutoyo 293‑180‑30 QuantuMike is a coolant proof micrometer that features a rapid measurement due to the 2mm of spindle feed for every thimble revolution. The patented ratchet thimble mechanism* helps ensure repeatable results by transmitting microvibrations along the spindle...

When connected to a PC’s USB port, the Mitutoyo USB SPC data collection Input Tool is automatically recognized as an HID (Human Interface Device) keyboard device – a standard Windows® driver. No special software is required for data management. A...

The 4 piece Mitutoyo Machinist Caliper and Micrometer Tool Kit (64PKA070A) is examined in this week’s unboxing video. This machinist tools kit contains the following items: • 101-117-Outside Micrometer (Friction Thimble Type) (Range: 0–1”, Graduation: .0001”) • 129-132-Depth Micrometer (with...

In this episode of Tool Tip, we discover how to send detailed traceability information from MCOSMOS to MeasurLink Real-Time Software using Structured Sublot.

This week we see what’s inside the Mitutoyo SERIES 568 – ABSOLUTE Digimatic Bore Gage Kit.

The EC-100 Digimatic SPC display can be connected to Mitutoyo devices with Digimatic output, including micrometers, indicators, calipers and LGS/LGD Linear Gage to assist with statistical process control.

Looking for the Mitutoyo 513‑402‑10T Dial Test Indicator? Check out this full unboxing video.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to use channel mapping in MeasurLink. Mitutoyo’s MeasurLink 8 Real-Time Professional Edition enables customers to connect and acquire data from Mitutoyo Coordinate Measuring Machines, Vision and Form Measuring Systems via native integration (DDE).

In this video we show how to use a dial bore gauge, telescoping gages, digital bore gauges, digital indicator bore gage and the Mitutoyo Borematic to accurately measure a cylinder bore, taper and out-of-round. Learn about Measuring an Engine Cylinder...

The U-WAVE system enables easy wireless data collection from a measuring tool to a PC using the Digimatic protocol. Measurement efficiency is improved by eliminating the long and cumbersome data management cables. The user-friendly interface allows data to be loaded...

What to know how to calibrate your metrology tools? In this episode of Metrology Training Lab, we discuss Calibration, which is critical to maintaining the quality and accuracy of your measuring equipment and what it means to calibrate your tools.

The DP-1VA allows for SPC data collection from a Digimatic gage. This metrology data can be stored in the device, sent to a software like Excel, IT-Pak or data logging software such as MeasurLink, and printed. In this video, we...

What happens to solar powered calipers and indicators from Mitutoyo during a total eclipse? We traveled to Southern Illinois to see if our solar powered tools continue to work during the Great American Solar Eclipse.

The i-Checker is designed to calibrate a variety of indicators, including bore gages, Digimatic indicators, dial indicators, dial test indicators and linear gages.

Mitutoyo is pleased to announce the ABSOLUTE AT1100, the latest generation of assembly-type linear scales that incorporate Mitutoyo’s electromagnetic induction technology, which provides resistance against contaminants such as cutting fluids, oil and water.

Dial Test Indicators from Mitutoyo provide enhanced durability, sensitivity and readability for metrology applications and offer a choice of dial position. Four models are available, each with a different orientation of the dial to allow the best visibility in any...

Linear Height LH-600E – Series 518 -High Performance 2D Measurement System. Series 518 FEATURES: • Excellent accuracy of (1.1+0.6L/600)μm with 0.1μm/0.5μm resolution/repeatability. • Perpendicularity (frontal) of 5μm and straightness of 4μm are guaranteed. • Pneumatic full/semi-floating system allows adjustment of...

Learn how to read an imperial, inch vernier caliper. This video shows how to read vernier calipers that can be used for outside, inside, and depth measurements.

Mitutoyo product demo video showing how to read a Mitutoyo micrometer. This video shows the steps required to read a standard micrometer or vernier micrometer.

Product demo video showing how to use a Vernier Micrometer.

Product demo video showing how to read a Dial Caliper.

Mitutoyo product demo video showing the proper use of Digital Caliper.

Mitutoyo product demo video showing how to use a Digital Micrometer.

Mitutoyo product demo video showing the use of Vernier Calipers.

Product demo video showing the proper use of Dial Calipers.

Making Sense of Non-Contact SensorsWebinar: Both contact and non-contact sensors play a prominent role in the industry, however, this webinar focuses on non-contact sensors. There are various sensors and methods of data acquisition (laser, radar, etc.), all with advantages and...

Statistical process control (SPC) needs to start at the point where parts are created. The X-Bar & R chart, Histogram chart and capability indexes provide three vital steps in observing your manufacturing process, from start to finish, to ensure that...

Learn the basic setting of the Mitutoyo Display Unit for Linear Scale. The KA-200 Counter features absolute and incremental modes (10 presets each), non-linear and linear error compensation, adjustable high-brightness, high-refresh rate LED displays, calculator function and outputs data into...

The new MITUTOYO Quick Vision Active system enters the market in a choice of two different measurement ranges: as “202” model with 250 x 200 x 150 mm and as “404” with 400 x 400 x 200 mm. Both variants...

MeasurLink Sales Specialist Jeremy Banks demonstrates MCOSMOS Programming.

MeasurLink Sales Specialist Jeremy Banks demonstrates MCOSMOS DDE header transfer.

MeasurLink Sales Specialist Jeremy Banks demonstrates exporting data from MCOSMOS.

MeasurLink Sales Specialist Jeremy Banks demonstrates MeasurLink DDE Settings.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to create a routine in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates reports in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to open/close and resume/suspend programs in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates traceability in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates process analyzer filter in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates the process manager merge feature in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to collect data using Real-Time Pro in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates Assignable Cause and Corrective Action in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to configure data tests in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates the different views in MeasurLink.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to export reports in MeasurLink to Excel.

How fast is the IP65 Coolant Proof QuantuMike from Mitutoyo? In a word, FAST! Featuring a faster measurement with 2mm per rev. instead of the standard 0.5, the Mitutoyo QuantuMike is the micrometer you’ve been waiting for. Features: • Faster...

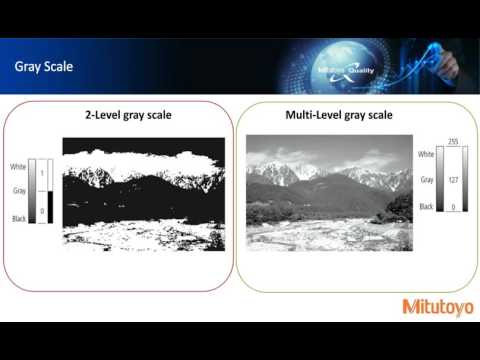

The way a vision system detects and collects data points can be a mystery to some. A vision system is a non-contact, non-destructive method for dimensional measurement and has the ability to “see” the features of interest vs. tactile measurement...

Mitutoyo Knife Edge Calipers are specially designed for inside measurements in hard-to-reach places.

Pointed spindle and anvil for measuring the web thickness of drills, small grooves, keyways, and other hard-to-reach dimensions.

Specially designed for center to center distance measurements on the same and offset planes.

The Mitutoyo 573 series digital neck caliper uses Mitutoyo’s ABSOLUTE linear encoder technology and has flat type jaws for outside dimension (OD) measurements of grooves and recesses. This caliper has accessible function control buttons, and uses both inch and metric...

Due to the low measuring force, these calipers are ideal for elastic or resilient workpieces such as plastic parts and rubber parts that standard calipers cannot measure.

The Mitutoyo Blade Micrometer’s anvil and the spindle have a blade for measuring the groove diameter of shafts, keyways, and other hard-to-reach areas.

The Disk Micrometer is designed to easily measure root tangent length of spur gears gears and measuring the thickness of sheet materials like paper, cardboard, rubber, and plastic.

Mitutoyo Caliper Type Micrometers have caliper type jaws making it easier to measure inside features with the accuracy of a micrometer.

FT Gearing buy Mitutoyo measuring and scanning technology.

Mitutoyo Sheet Metal Micrometers are used to measure the thickness of sheet metal, paper, plastic, and rubber parts where a deep throat micrometer is required.

Mitutoyo V-Anvil Micrometers are useful for measuring pitch diameters of taps which have a small diameter by using single-wire method. Measures the outside diameter of cutting heads with odd number of flutes such as taps, reamers and end mills.

Headquartered in the Chicago suburb of Melrose Park, IL, Dynamic Manufacturing is a TS 16949, ISO 14001 and WBENC-certified woman-owned and -operated business with operations covering engineering, machining, assembly and dynamometer testing. Founded in 1951 by John Partipilo, who started...

The 2.4-inch color graphic LCD provides excellent readability and an intuitive display that is easy to negotiate. The LCD also includes a backlight for improved visibility in dark environments.

In this webinar, we will introduce the MiCAT Planner automatic measurement program generation software that uses 3D CAD models and Product and Manufacturing Information (PMI) to enable one-click automated generation of measurement programs. With this new program, a complex program...

See how to set the segments on a Mitutoyo Laser Scan Micrometer. Using a Mitutoyo LSM-6900, Tyler Duncanson walks through the steps of setting segments.

See how to set the tolerance of a Mitutoyo Laser Scan Micrometer. Using a Mitutoyo LSM-6900, Tyler Duncanson walks through the steps of setting the tolerance.

See how to set the resolution of a Mitutoyo Laser Scan Micrometer. Using a Mitutoyo LSM-6900, Tyler Duncanson walks through the steps of setting resolution.

Mitutoyo Litematic and Litematic Head – Series 318: • The Litematic is designed for measuring easily-deformed workpieces and high-precision parts, with extra-low measuring force of 0.01N. • 0.15N and 1N types are capable of measuring at a certain measuring force...

A conventional Digimatic indicator simply displays a spindle displacement, but the Calculation-Type Digimatic indicator incorporates an internal calculation function in place of spindle displacement. With fixtures, measurements such as feeler, inside diameter and radius of curvature measurement can easily be...

A benchtop profile projector based on a vertical beam, telecentric optical system for distortion-free viewing on a 14″ diameter protractor screen. • Bench-top model that uses horizontal optical system. • Suitable for thread pitch measurements—blurred or distorted images will not...

Check Points for Measuring Instruments – This video covers the proper use of Thickness Gages from Mitutoyo.

Check Points for Measuring Instruments – This video covers the proper use of Vernier Holtests from Mitutoyo.

Check Points for Measuring Instruments – This video covers the proper use of Digimatic Holtests from Mitutoyo.

Mitutoyo’s Gold Care Limited Edition Productivity Program – Support and Service.

Mitutoyo America Corporation is a sales, marketing, and most importantly a service organization that was established in the United States by Mitutoyo Corporation in 1963. Since day one of operations, supporting customers has been the first priority. Initially we provided...

Mitutoyo offers four main Rockwell Hardness tester designs: The Dial HR210, the Digital HR320 MS Rockwell and Superficial model, the HR430 model featuring the dial a weight system and automatic brake/start mechanism in both Rockwell Only and the Rockwell/ Superficial...

Our full range of roundness and cylindrical-form measuring instruments come with extensive analysis features that accommodates a wide variety of workpieces. Our PC based Roundtest products incorporate accessible Roundpak softwa with patented continuous internal/external diameter measurement reducin the need to...

Mitutoyo LSM Tutorial – Episode 05 This episode shows how to quickly set up Upper and Lower Tolerance Limits in a Mitutoyo Laser Scan Micrometer.

Mitutoyo LSM Tutorial – Episode 04 It’s easy to measure multiple diameters on a single or multiple parts using Mitutoyo’s Laser Scan Micrometers. This episode shows how it can be done extremely quickly by simply sliding the part through the...

Mitutoyo LSM Tutorial – Episode 03 The resolution for the Laser Scan Micrometer can be changed in the Basic Setup Menu. The 1st option is resolution setting. The manual will show a chart of setting vs resolution for your Laser.

Mitutoyo LSM Tutorial – Episode 02 This episode shows how to change units from metric (mm) to inches.

Mitutoyo LSM Tutorial – Episode 01 Most customers are using Laser Scan Micrometers to measure diameters. In this episode we will explain the basic principle of the Mitutoyo Laser Scam Micrometer, how to measure a diameter by changing segments, and...

Gold Care is Back by Popular Demand. Your ultra-precise part inspection process demands the best. But the cost of ownership issues drives a strong bottom line focus as well. Our Gold Care Program lets you achieve both. Simply it’s the...

Curtis Stubbs answers a question posted by daikaiju20: i use these calipers at work and recently they display 8.7105 when i power on, have to zero out each time i power on. anyone know what will return it to zero...

Mitutoyo America Corporation opened the doors to its brand new corporate headquarters on Monday, October 14th to over 200 special guests.

Mitutoyo has a wide variety of near-line and in-line gage technologies developed for the shop floor. Here we see one of the latest innovations in our Mach line of CMM’s the MACH Ko-Ga-Me.

This video is a quick introduction to precision gage blocks which are the primary standards vital to dimensional quality control in the manufacture of parts. Mitutoyo offers a complete selection of gage blocks available in a choice of rectangular or...

Learn to assemble and calibrate bore gages from Mitutoyo.

This video covers replacing the battery in the Mitutoyo IP67 Caliper and setting the zero point. In addition to the quick demo, there are some great tips on using Mitutoyo’s Coolant Proof IP67 Caliper.

This demo video covers replacing the battery in the Mitutoyo Constant Force Caliper and the proper procedures for measuring resilient surfaces. There is also a comparison measurement between the Mitutoyo Constant Force Caliper and a standard Mitutoyo Caliper on a...

Product demonstration of the new Mitutoyo America MACH Ko-ga-me CMM.

Dirk from Quality Digest Live does an amazing job with this demo of the Mitutoyo MDH Micrometer.

Lifting lever installation instructions.

Battery (938882) installation instructions for Mitutoyo Calipers.

Faster measurement is achieved with our QuantuMike by using a coarser thread which feeds the spindle by 2 mm per revolution instead of the standard 0.5mm. The QuantuMike offers IP65 level protection and is equipped with a function lock feature...