Introduction to M3 on Quick Image System

Mitutoyo’s Quick Image systems, now integrated with Metlogix M3 software, creates a powerful combination that brings the latest advancements in metrology to the forefront of precision measurement, offering users an unprecedented level of accuracy and efficiency.

Designed for industries where precision and quality are real requirements, M3 on the Quick Image is ideal for applications ranging from aerospace to automotive manufacturing. By combining multi-touch control with intuitive software interfaces, M3 ensures that complex measurements can be performed quickly and accurately, even by operators with minimal training.

Innovative Features of M3 Software

Innovative Features of M3 Software

M3 software stands out for its user-centric design and powerful capabilities. One of its key features is the multi-touch control system, which allows users to interact with the software through simple gestures like pinch, zoom, and swipe. This feature significantly enhances the user experience, making it easier to perform feature measurements, manipulate data, and generate reports.

Additionally, M3 software incorporates advanced sub-pixel processing, a technology that improves edge detection accuracy by removing the limitations imposed by pixel size. This results in highly accurate measurements, even for the most complex parts. The software also includes a range of measurement tools, such as GD&T capabilities, which are essential for maintaining compliance with industry standards.

Benefits of Quick Image System Integration

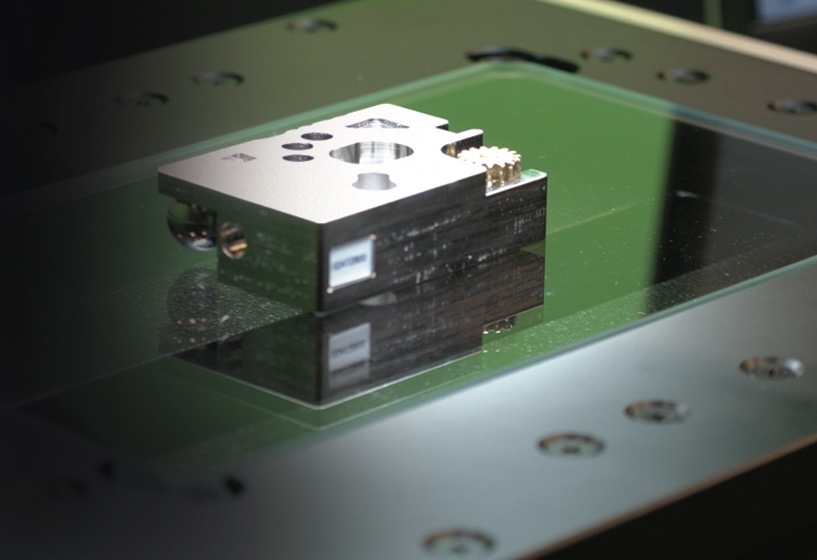

The integration of M3 software and interface with Mitutoyo’s Quick Image system creates a beneficial collaboration that elevates the capabilities of both platforms. Quick Image is renowned for its high-precision optics and robust construction, allowing it to measure even difficult-to-image edges. When paired with M3 software, the Quick Image hardware becomes even more powerful, offering features like a wide field of view and the ability to perform non-contact measurements with unparalleled accuracy at larger lengths and distances, This integration also simplifies the measurement process, as M3’s intuitive interface reduces the need for extensive training, enabling operators to achieve precise results quickly.

Applications in Aerospace and Other Industries

Industries such as aerospace, automotive, and high-precision manufacturing stand to benefit from the Quick Image system being integrated with M3. In aerospace manufacturing, for instance, the ability to measure complex components with extreme accuracy is critical to ensuring the safety and performance of aircraft and its every component. The Quick Image with M3 simplifies this process by providing a range of measurement tools that can handle everything from geometric tolerances to pattern recognition.

Similarly, in the automotive industry, where the precision of every component affects the overall performance of a vehicle, M3 on Quick Image offers a reliable solution for quality control and compliance.

How Quick Image with M3 Enhances Workflow Efficiency

Efficiency is a key consideration in any manufacturing environment, and the Quick Image with M3 software is designed to optimize workflow at every stage. M3 software automates many of the measurement processes, reducing the need for manual intervention and allowing operators to focus on more critical tasks. This is particularly beneficial in high-volume production settings where speed and accuracy are necessary to fill customer orders in the time settings they demand within the specifications required. The Quick Image system’s ability to handle large batches of workpieces simultaneously further enhances this efficiency, making it an ideal choice for industries that require rapid throughput without sacrificing precision.

Data Management and Reporting with M3 Software

Data Management and Reporting with M3 Software

Data management is a critical component of any quality control process, and M3 software excels in this area. It provides a comprehensive suite of tools for managing measurement data, generating detailed reports, and ensuring compliance with industry standards.

The software’s flexibility allows users to customize reports to meet specific requirements, whether they need simple CSV files or more complex formats. Additionally, M3 software supports integration with other systems, such as ERP and MES platforms, enabling seamless data flow across the manufacturing process.

Why Choose the Quick Image with M3 for Precision Measurement?

Choosing the right precision measurement system can be a challenging task, but the integration of M3 software on the Quick Image offers a powerful solution that combines accuracy, efficiency, and ease of use. Whether you’re an engineer, quality manager, operations director, or technical buyer, this system provides the tools you need to achieve reliable, repeatable results. With its advanced features, seamless integration, and robust support from Mitutoyo, the Quick Image with M3 integration is not just an upgrade; it’s a revolution in precision measurement. Explore how this innovative system can elevate your measurement capabilities and transform your quality control processes.