Today, achieving pinpoint accuracy for your parts or product is absolutely crucial. Mitutoyo Profile Projectors are designed to meet the high demands of precision measurement, making them a vital tool for professionals in various industries.

From manufacturing floors to quality control labs, our profile projectors enable operators to verify the dimensions of small, complex components with confidence. This blog post will explore the key features, benefits, and real-world applications of Mitutoyo’s Profile Projectors, revealing why they are a trusted solution for accurate and reliable measurement.

Understanding Profile Projectors and Their Importance

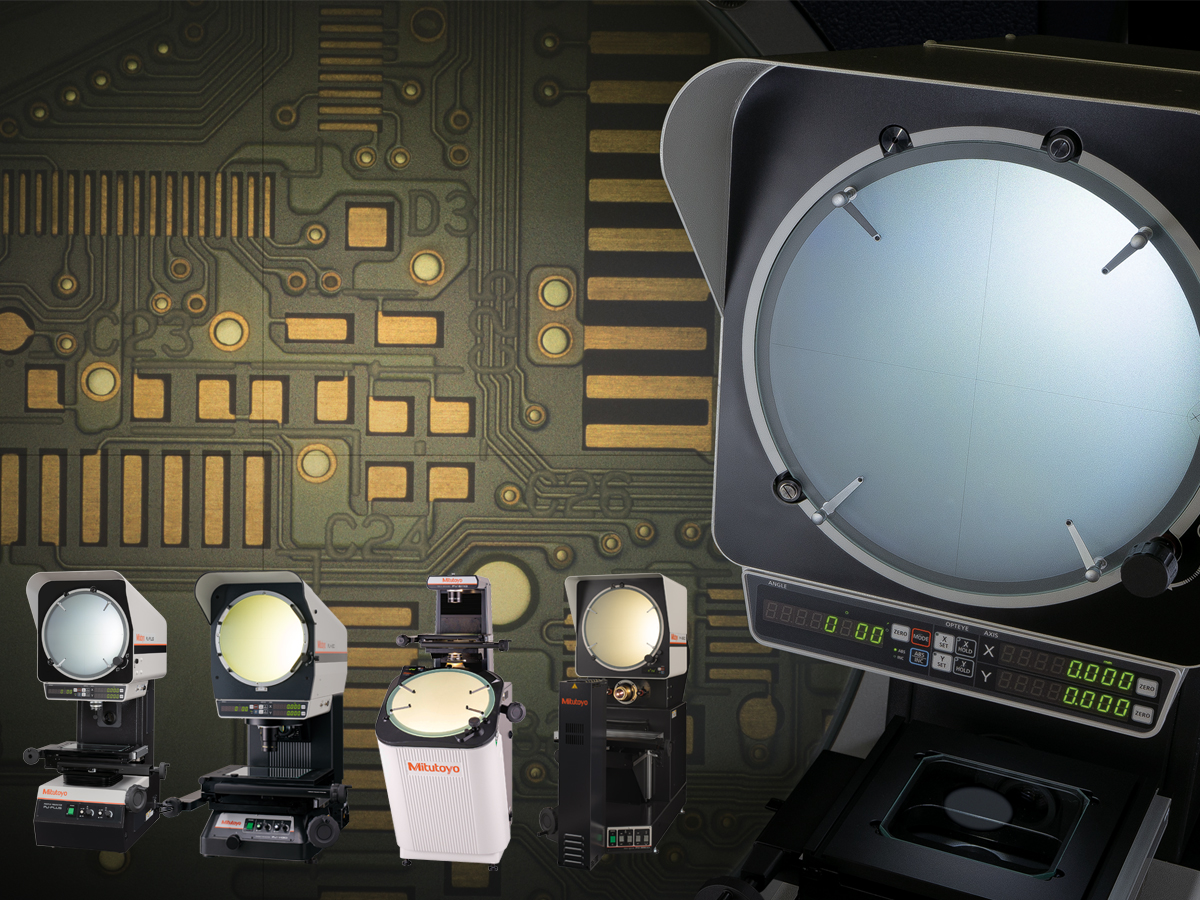

Profile projectors, also known as optical comparators, are essential tools used for inspecting and measuring the dimensions of various objects. They project an image of the part onto a screen, allowing for easy comparison to the specifications of a technical drawing.

This method offers a non-contact form of measurement, making it ideal for delicate components that cannot withstand physical touch. For industries where precision is critical—such as aerospace, automotive, and medical devices—profile projectors ensure that components are measured accurately without risking damage.

Manufacturers rely on profile projectors to check dimensions like lengths, angles, and radii with exceptional accuracy. These devices are especially beneficial for quality control, where exact specifications are mandatory to meet industry standards and prevent costly defects.

Key Features and Benefits of Mitutoyo’s Profile Projectors

Mitutoyo Profile Projectors are known for their advanced design and exceptional performance. Here’s a closer look at the standout features and the benefits they bring to the table.

Unmatched Precision and Accuracy

Unmatched Precision and Accuracy

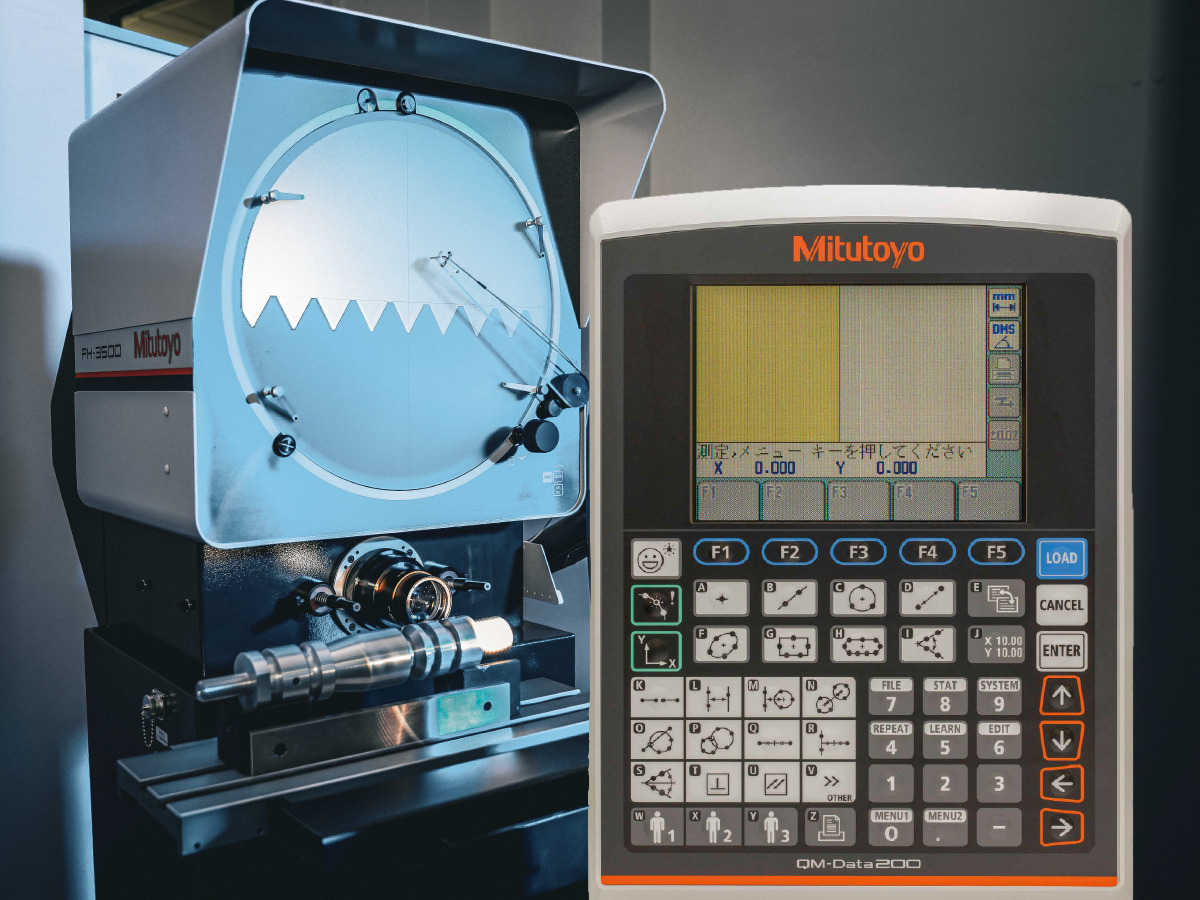

At the core of Mitutoyo profile projectors is their exceptional precision. Equipped with high-quality optics and innovative measurement systems, these projectors allow users to view even the smallest details with clarity.

For manufacturing professionals and engineers, this means fewer errors in measurement, ensuring that parts meet their exact specifications. Whether it’s measuring a minute screw thread or a complex component, Mitutoyo’s projectors ensure results are consistently accurate.

Versatility in Various Applications

One of the key advantages of Mitutoyo profile projectors is their versatility. These tools are designed to handle a wide range of measurement tasks, making them useful in numerous industries.

Whether you’re working with metal parts, plastic components, or even delicate electronics, Mitutoyo’s projectors can provide precise measurements. This versatility makes them an invaluable resource in quality control, ensuring that your production meets stringent standards.

Reliability in Demanding Environments

Manufacturing environments are often demanding, with harsh conditions and tight tolerances. Mitutoyo’s profile projectors are built to withstand these challenges, maintaining their accuracy and performance even in tough settings.

They are constructed with durable materials and designed to provide long-lasting reliability, making them a sound investment for companies that need consistent measurement accuracy.

Real-World Applications of Mitutoyo’s Profile Projectors

Mitutoyo’s Profile Projectors aren’t just theoretical tools—they are in use across the globe, helping companies maintain high standards of quality and precision.

Use in Manufacturing Industries

Use in Manufacturing Industries

In manufacturing, precision matter with every single part and every single measurement. Profile projectors from Mitutoyo are widely used to ensure that components meet their design specifications. Whether it’s in automotive or aerospace production, these projectors help manufacturers confirm that each part matches the blueprint exactly. In industries where even a small deviation can result in failure, the use of profile projectors is vital to maintaining product integrity.

Applications in Quality Control and Engineering

Engineers and quality control managers rely on profile projectors to verify that their products are up to their given specifications and standards. In sectors like electronics, medical devices, and automotive engineering, precision measurements are crucial for both safety and performance.

Mitutoyo’s Profile Projectors play a key role in ensuring that every part—no matter how small or complex—is inspected with the highest level of accuracy.

Why Choose Mitutoyo for Precision Measurement

Why Choose Mitutoyo for Precision Measurement

Mitutoyo stands out in the field of measurement tools due to its commitment to quality and innovation. Their profile projectors represent the best in precision technology, offering unmatched accuracy, reliability, and ease of use.

Whether you are a manufacturing professional, quality control manager, or engineer, Mitutoyo’s profile projectors provide a solution that you can trust for your most demanding tasks. With decades of experience in the industry, Mitutoyo continues to be a leader in measurement solutions.

Conclusion: Enhancing Precision in Your Operations

Achieving precision in manufacturing and engineering is not just a goal—it’s a necessity. Mitutoyo’s Profile Projectors offer a proven way to enhance the accuracy of your measurements, ensuring that every component meets its specifications.

Invest in Mitutoyo profile projectors to elevate the quality of your products and streamline your production processes. Learn more about how these tools can help your business stay at the forefront of precision measurement.