Achieve Faster, More Accurate Gear Measurements with GEARPAK

Achieve Faster, More Accurate Gear Measurements with GEARPAK

GEARPAK is revolutionizing how manufacturers handle gear measurements. With an array of automation features, real-time visualization, and seamless CMM integration, GEARPAK allows manufacturers to significantly reduce manual effort and improve measurement accuracy.

Whether you’re an engineer looking to streamline processes or a manager seeking consistent quality, GEARPAK offers the tools to enhance your gear inspection workflows and ensure precision. This blog post will explore how GEARPAK can help you achieve faster, more accurate results, making it an indispensable solution for your measurement needs.

Automate Gear Measurements with GEARPAK

Automation is key to improving both speed and accuracy in gear measurements. GEARPAK reduces manual setup time by automating complex measurement routines that previously required significant operator involvement. With fewer interactions between operators and the measurement process, GEARPAK eliminates inconsistencies caused by human error. This leads to more reliable results across multiple measurement cycles.

By leveraging 4-axis nominal scanning technology, GEARPAK enhances the precision of measurements while reducing the chances of operator missteps. Automation enables machines to take control of the process, ensuring every step follows the intended parameters without deviation. Ultimately, the time savings and accuracy gains from GEARPAK’s automation feature translate into higher productivity and reduced operational costs.

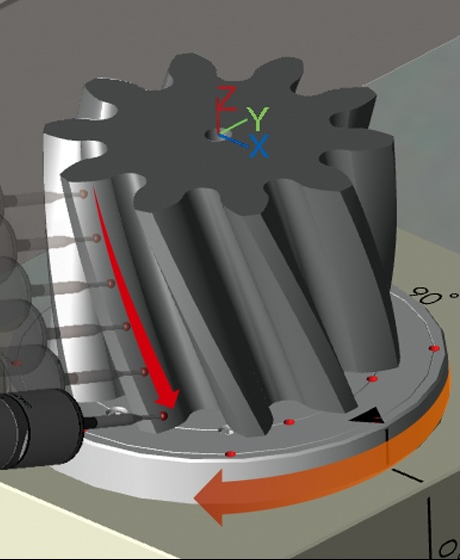

How 4-Axis Nominal Scanning Reduces Operator Errors

The inclusion of 4-axis nominal scanning in GEARPAK represents a major advancement in precision gear measurement technology. Traditionally, gear inspections often rely on manual setups, which can be prone to operator error due to inconsistencies in alignment, setup, or interpretation. With 4-axis nominal scanning, the measurement process becomes largely automated, ensuring a higher degree of accuracy by reducing reliance on human intervention.

In practical terms, the 4-axis scanning feature allows the measurement system to assess the gear from multiple angles and dimensions simultaneously. The four axes refer to the system’s ability to rotate and measure the gear not just horizontally and vertically, but also along additional rotational axes, covering complex geometries with pinpoint accuracy. This multi-dimensional approach ensures that every aspect of the gear, including its teeth profiles, pitch, and overall shape, is measured in relation to its nominal design specifications.

By scanning across these four axes, GEARPAK can quickly detect even the smallest deviations from the desired geometry—irregularities that might otherwise be missed in traditional 2- or 3-axis setups. This is particularly beneficial in high-precision industries like aerospace, automotive, and medical device manufacturing, where even minute deviations can result in performance failures or costly rework.

Additionally, because the 4-axis system reduces manual input, the risk of human error is significantly lowered. Whether it’s slight misalignments during setup or misinterpretation of measurement data, these potential pitfalls are minimized. Operators can trust that the system is providing consistent, accurate measurements, reducing the need for repeated inspections, and ensuring that gears meet the highest quality standards. This level of precision is critical for ensuring long-term durability and performance in applications where reliability is non-negotiable.

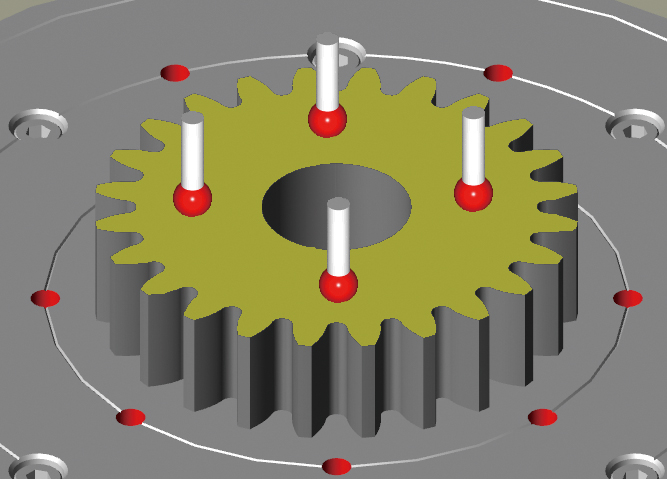

Gain Instant Feedback with Real-Time Visualization

Gain Instant Feedback with Real-Time Visualization

Real-time feedback during the measurement process is a game-changer for both operators and engineers. With GEARPAK, the moment a gear is inspected, you receive immediate feedback on its performance. This real-time visualization allows for quicker identification of errors and provides the opportunity to make adjustments instantly, minimizing wasted time and materials.

The software displays visual data as measurements are taken, enabling operators to quickly detect any deviations from expected results. Whether it’s out-of-tolerance features or misalignments, GEARPAK gives you the tools to correct issues on the spot. This ultimately leads to fewer rejected parts and more efficient production cycles, making GEARPAK an essential tool for achieving high-quality standards.

Correct Errors in Real-Time with GEARPAK’s Interface

The intuitive interface of GEARPAK allows users to monitor the measurement process in real-time. By displaying the data in a visual format, operators can spot anomalies immediately and take corrective action before proceeding with additional inspections. This real-time interaction ensures that errors are caught early, reducing the need for rework, and saving both time and resources. For engineers focused on maintaining strict quality standards, GEARPAK’s real-time feedback is an invaluable tool.

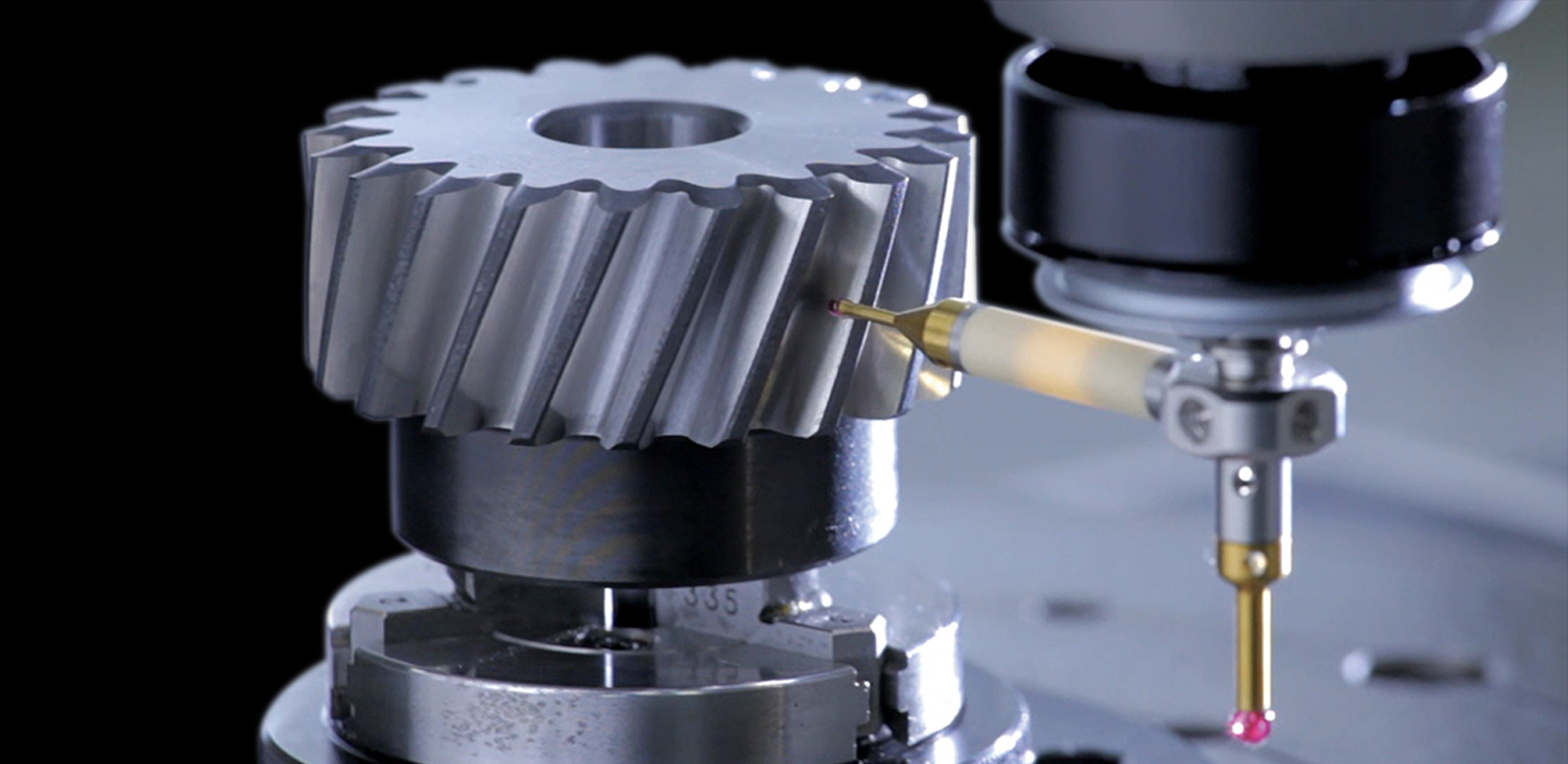

Seamlessly Integrate GEARPAK with Your CMMs

Seamlessly Integrate GEARPAK with Your CMMs

GEARPAK was designed to work in harmony with your existing CMM setup, making the transition to automated gear measurements simple and seamless. Its compatibility with a wide range of CMMs means that integrating GEARPAK into your workflow doesn’t require overhauling your current system. This flexibility ensures that GEARPAK can fit into nearly any measurement environment, regardless of the specific machines in use.

GEARPAK’s ease of integration extends to its setup process as well. The software installs quickly, and operators can start utilizing its advanced features almost immediately. This ensures that you can benefit from GEARPAK’s automation and real-time visualization features without extended downtime during the installation process.

Quick and Easy Installation into Existing Setups

Installing GEARPAK into an existing CMM setup is straightforward. The software is designed for ease of use, and the installation process is well-documented, allowing you to get up and running with minimal disruption. Whether you’re working with newer or older CMM models, GEARPAK is compatible with a variety of machines, ensuring that your transition to more automated, accurate gear measurements is smooth and efficient.