General Manufacturing shops allow for faster high precision manufacturing processes—but even rapid production still requires rigorous quality control. End to end shop floor metrology solutions from Mitutoyo help ensure that machine-tooled parts and products meet your tolerances.

General Manufacturing Realities

No two machining applications are the same. From standard lathes and milling machines to multiple access machines, cutters and lasers, each manufacturing tool comes with its own challenges for traceability and repeatability. What’s more, these measurements must be accurate, consistent and fast.

Efficiency Pressures

Faced with budgets and high demand, manufacturers attempt to reduce costs by speeding up production cycles and increasing throughput. However, this can lead to mistakes that have serious consequences, since error-ridden products require costly reproduction. To solve this, Mitutoyo has developed innovative technology and measuring devices that are highly accurate, fast and durable.

Industry Variations

Factory-floor applications of nearly every shape, size and space play a major role in countless industries. These industries measure diverse factors like roundness, roughness, hardness, length—or even multiple factors throughout the production process. Without an integrated, full-scope metrology solution, critical errors are possible.

Mitutoyo’s Expertise

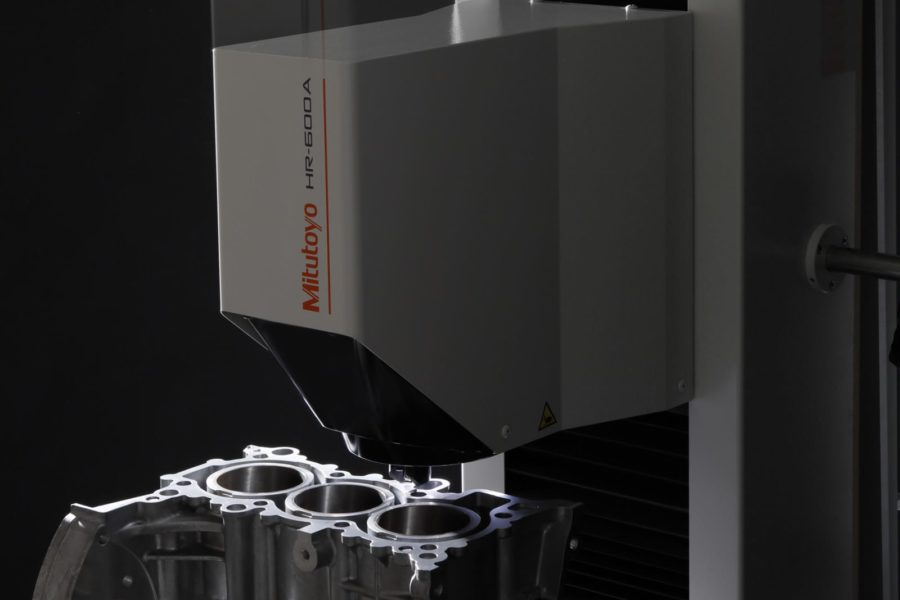

Mitutoyo partners with global manufacturers in a wide range of industries to deliver perfectly calibrated, reliable metrology solutions for machined products. Our efficient solutions run the gamut of metrology applications, allowing practically any manufacturer to rapidly ensure quality.

Traceability to NIST standards

Full range of solutions: in-line and offline, contact and non-contact

Coordinated software for efficient data storage and analysis

General Manufacturing Metrology Solutions by Mitutoyo

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

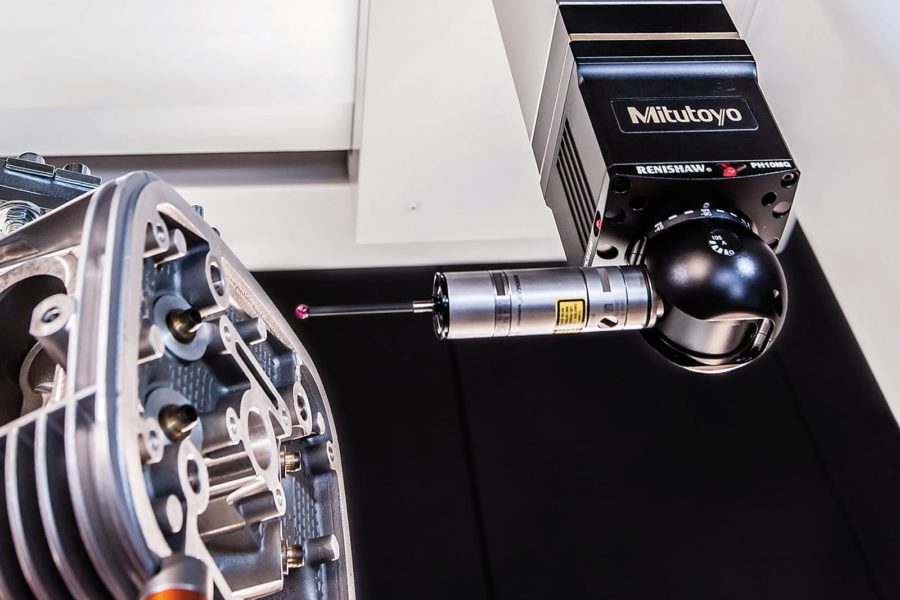

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

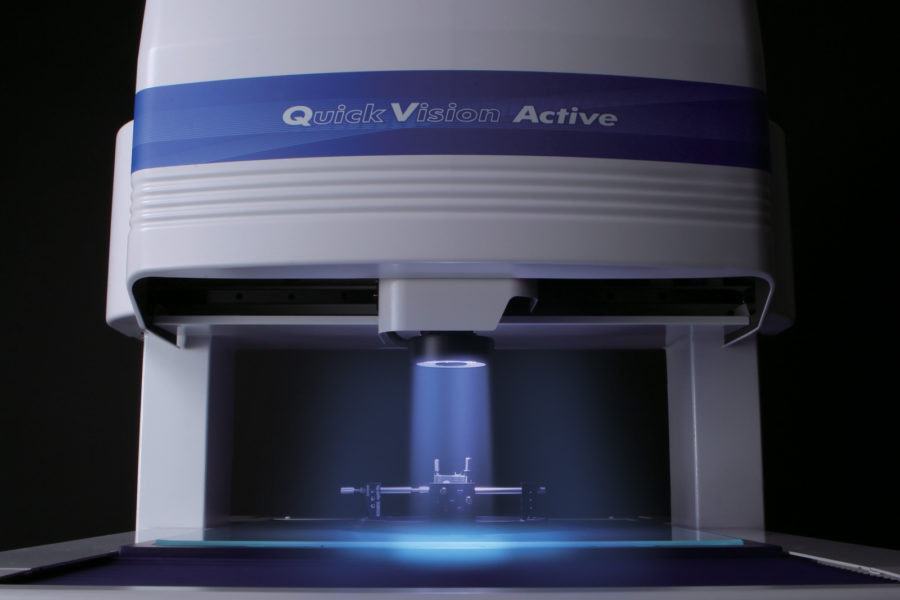

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

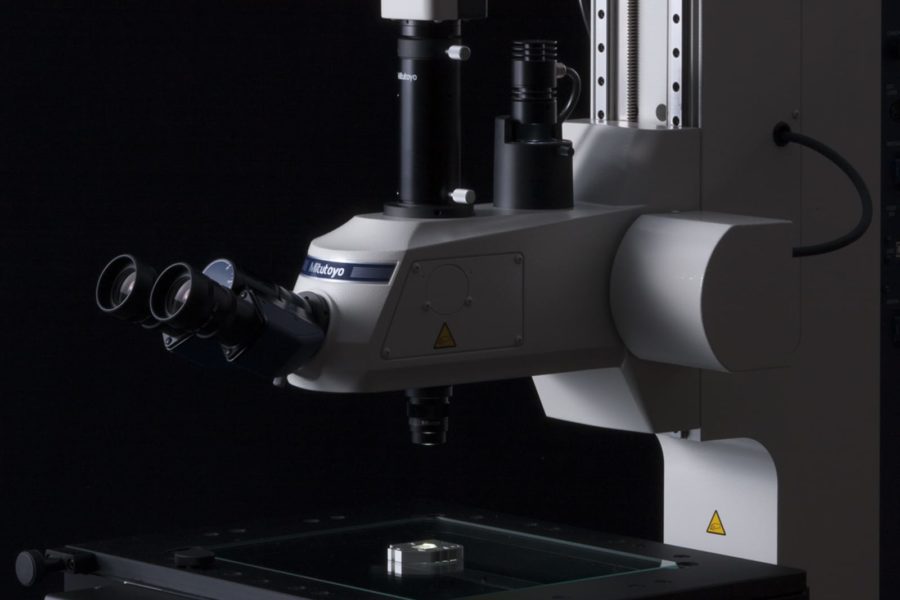

Our high-resolution microscopes and profile projectors measure minuscule electronic components with high accuracy and repeatability

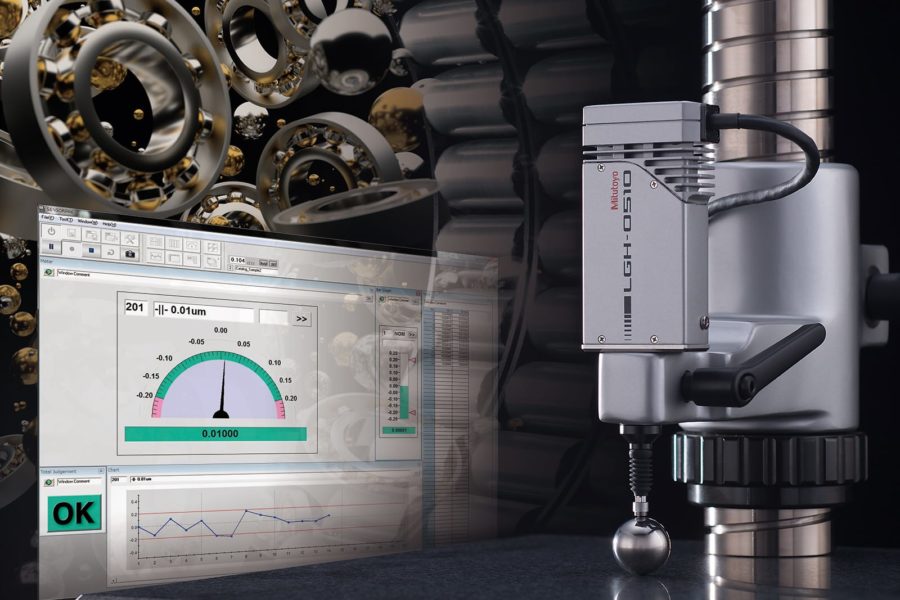

As an industry-leading provider of contact and non-contact sensor systems, Mitutoyo supports your strictest measurement needs

Our accurate, user-friendly testing equipment solutions set the industry benchmark for most standardized testing methods

Mitutoyo digital and linear measurement tools deliver ultimate precision, accuracy to in-house machine tool applications and manufacturing

Honing in on Manufacturing Tool Precision

The nickel-chromium-based super-alloy components from Hone-All Precision require deep hole boring to complete: a process that is notoriously difficult to machine. Find out how two-point bore micrometers from Mitutoyo allowed Hone-All to finish part-machined components exactly to spec and earn their customers’ confidence.

Join us for our 2nd annual BBQ at the Mitutoyo showroom in Renton. Come meet your local Mitutoyo Team

Join us for an Introduction to Coordinate Measuring Machines Webinar. In only 15 minutes you will learn….

Are you ready to take your skills to the next level? Join Mitutoyo at the NCSLI International Workshop 2025 and experience cutting-edge technology that will revolutionize the way you approach measurement. Don’t miss the chance to visit our booth and...

Looking to discover the latest cutting-edge technology in precision measuring instruments? Then look no further than our booth #1941 at Semicon West 2025!