To produce electronic applications effectively, two things are essential: precisely manufactured components, and a fast, seamless production cycle. Mitutoyo’s optical, vision, CMM and handheld metrology solutions help produce electronic components with even the tightest tolerances.

Electronic Industry Realities

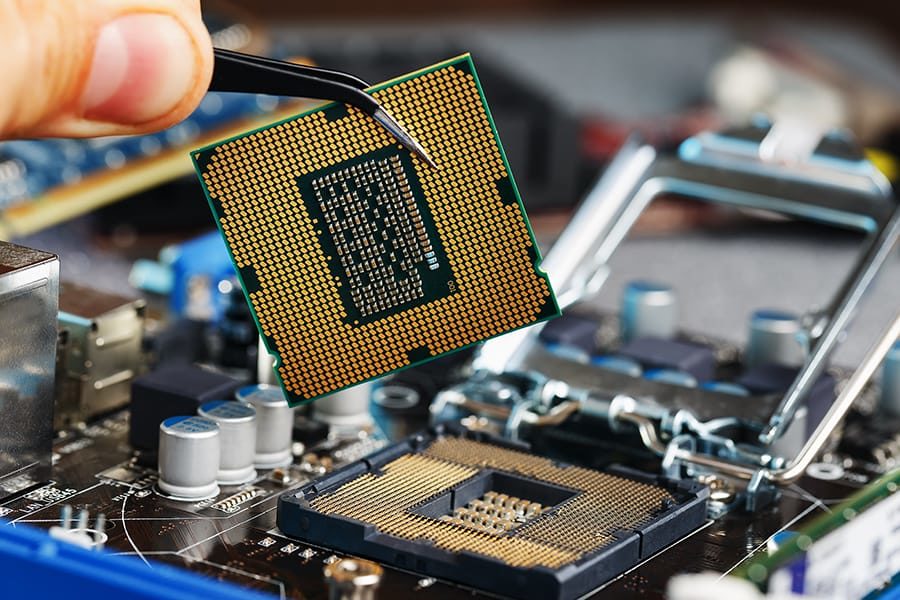

As microprocessors, semiconductors and other electronic components become ever-smaller, the importance of accurate microscopy continues to grow. In small footprints, the margin of error for measurement accuracy is virtually nonexistent. Only the most sophisticated and highest resolution metrology solutions can deliver the precision necessary for success.

Delicate Components

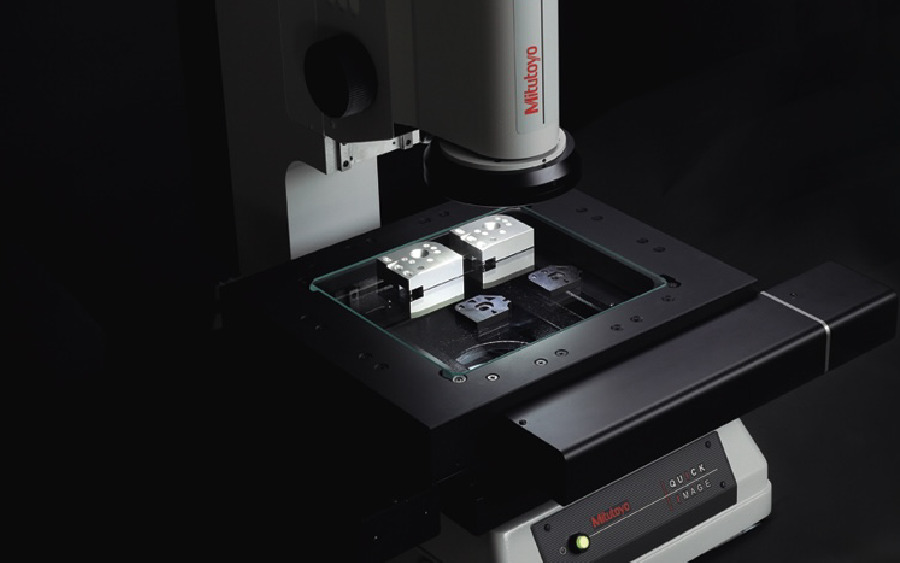

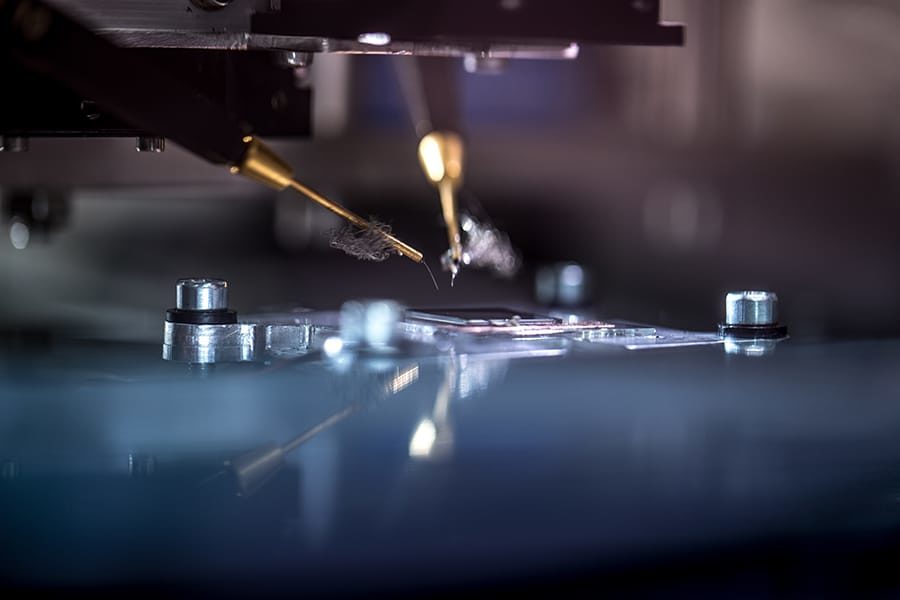

Today’s electronics manufacturers are tasked with delivering more processing power in less space—which requires smaller components, maximum efficiency and razor-sharp accuracy. Small components like wafers or comparators are often too fragile or sensitive for traditional contact metrology. Innovative Mitutoyo Vision Measuring Systems, microscopes and microscope objectives are able to quickly inspect fragile components without touch probes at incredible accuracies.

Rapid Iterations

Innovation moves fast in the electronics industry. Manufacturers must keep inspection speeds high to meet market demand and keep pace with new design elements. At the same time, these fast-moving and complex production processes must assure consistent accuracy and speed. Mitutoyo offers a variety of Vision Measuring Systems that feature high speeds, high accuracy and high throughput electronics manufacturers rely on.

Mitutoyo’s Expertise

Measuring delicate components requires microscopic accuracy, and Mitutoyo brings over 80 years of expertise in precise, reliable measurement. From micrometers and vision lasers with 0.1m resolution to bench-type non-contact CMMs, our electronics and semiconductor metrology equipment helps manufacturers ensure accurate production.

High-res optical solutions with high-contrast images across a broad light spectrum

Streamlined data acquisition to enable faster inspection speeds

Non-contact and vision measurement for small or delicate components

Electronics Metrology Solutions by Mitutoyo

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Our high-resolution microscopes and profile projectors measure minuscule electronic components with high accuracy and repeatability

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

As an industry-leading provider of contact and non-contact sensor systems, Mitutoyo supports your strictest measurement needs

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

The Manufacturing and Automation eXchange is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...