Touch, Measure, Report: The Future of Metrology

Touch, Measure, Report: The Future of Metrology

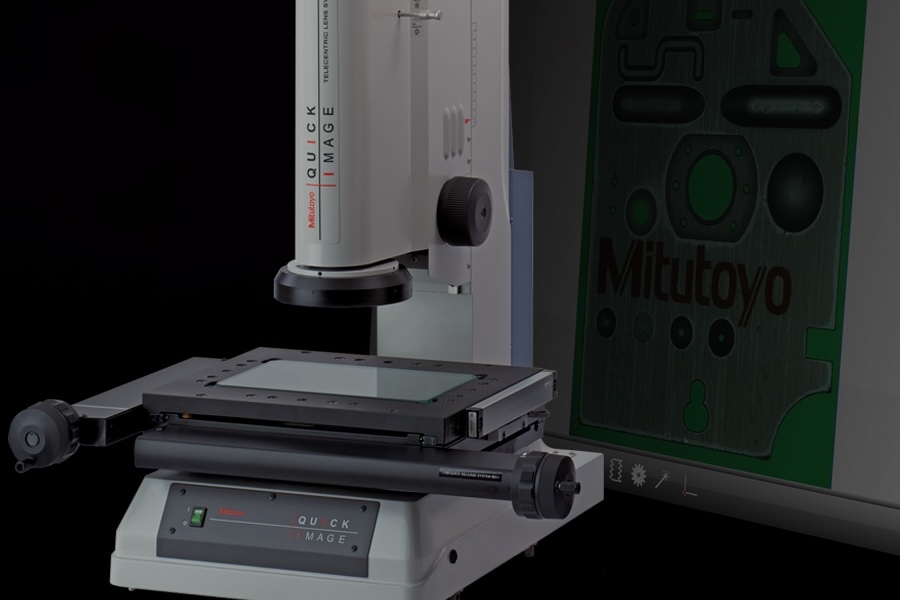

The landscape of metrology is rapidly evolving, with technology playing a pivotal role in improving accuracy, efficiency, and ease of use. One of the most innovative systems driving this change is the Metlogix M3 software on Quick Image (QI). By combining an intuitive multi-touch interface with Mitutoyo’s advanced optics and quality construction, the new Quick Image system promises to revolutionize how measurements are taken, analyzed, and reported across industries.

Designed to simplify complex measurements, M3 reduces the learning curve for operators and maximizes productivity by streamlining the measurement process into simple touch-based actions. Furthermore, its advanced reporting features ensure that data is not only collected with precision but is also managed efficiently for compliance and analysis.

User Experience: Simplifying Measurements with M3’s Intuitive Interface

The heart of the M3 system lies in its user-friendly multi-touch interface. Traditional metrology systems require multiple steps and manual inputs, but having Metlogix M3 technology on the Mitutoyo QI, these actions are reduced to simple gestures.

Operators can perform measurements with just a few touches on the screen, thanks to the system’s responsive interface and automated tools. Whether it’s zooming into a workpiece or detecting edges, the interface allows for greater precision with minimal effort. The entire process is designed to be intuitive, allowing even first-time users to achieve high-quality results with minimal instruction.

By simplifying the user interaction, M3 on QI system also reduces the chances of human error. Every function is accessible with a single touch, from focusing on a part to analyzing detailed measurements. This boosts productivity and allows for faster measurements, helping organizations maintain high levels of output without compromising accuracy.

The Power of Touch: Multi-Touch Interface Highlights

The Power of Touch: Multi-Touch Interface Highlights

One of the standout features of M3 on QI is its multi-touch capability. With M3, what used to take multiple steps can now be done with a few intuitive gestures. Operators no longer need to perform complex procedures to gather data.

This modern touch interface streamlines operations, letting users seamlessly switch between viewing angles, zooming into components, and recording measurements—all with intuitive finger movements. This system is particularly valuable in environments that demand both speed and precision.

Advanced Data Management: Streamlining Reporting and Compliance

Data reporting is one of the most critical aspects of metrology, and the Quick Image with M3 excels at it. By offering robust reporting tools, M3 ensures that the data captured during measurements is processed, analyzed, and shared efficiently.

With customizable reporting templates and the ability to integrate with various data formats, M3 makes it easy to generate accurate, compliant reports. These reports help teams quickly spot trends, make informed decisions, and ensure that the organization adheres to regulatory standards.

Data Accuracy and Reporting Efficiency

The reporting capabilities of M3 are designed to reduce the margin of error. The M3’s advanced reporting tools ensure that data is not only accurate but also easy to analyze and share, saving time and reducing errors.

The system’s software collects, stores, and processes data automatically, significantly reducing the need for manual input and ensuring high accuracy levels. Additionally, its seamless integration with other software systems enhances communication across teams.

Reporting and Data Management: Ensuring Compliance with Ease

The need for compliance in metrology cannot be overstated, and the Quick Image with M3 addresses this by simplifying how reports are generated, and data is stored. Compliance becomes a seamless process when you have a system designed to handle the complexities of data management automatically.

From initial data capture to the final reporting stage, M3 ensures that all information is traceable, compliant with industry standards, and ready for audit at any time. This reduces the workload on teams and ensures peace of mind when facing regulatory scrutiny.

Real-Time Insights with Advanced Reporting Features

M3 offers advanced real-time data management. Its robust reporting features allow for immediate insights, enabling faster decision-making and improving operational efficiency. These real-time insights help prevent quality issues before they escalate, saving time and resources.

Quick Image Beyond M3 Software

Mitutoyo Quick Image vision systems offer distinct advantages over similar products, particularly in precision, usability, and efficiency. This system is designed with high accuracy and stability, achieving a field view accuracy of ±4µm and stage accuracy of ± (3.5 + 0.02L) μm. Such precise accuracy across a variety of workpiece sizes meets the stringent demands of industries where tight measurement tolerances are critical. The system’s large field of view, combined with a sophisticated stitching algorithm, enables capturing large workpieces in multiple fields of view, significantly improving operational efficiency.

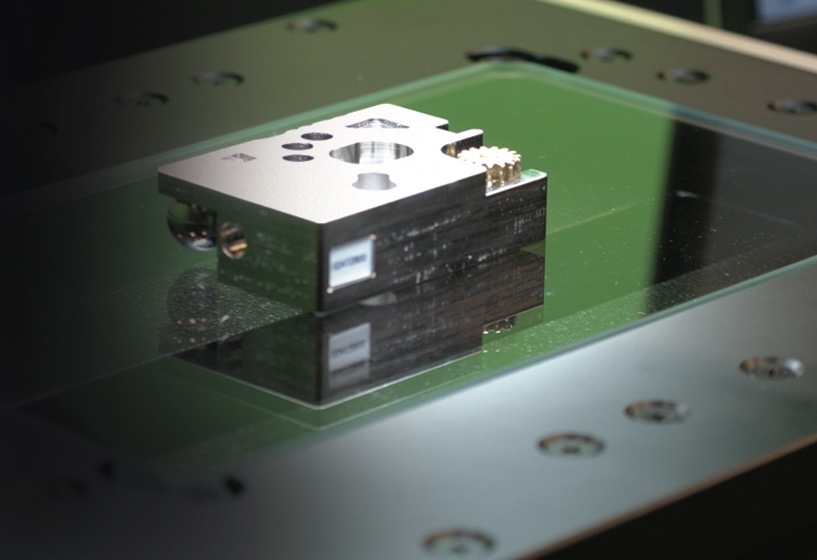

Robustly designed both optically and mechanically, the Quick Image system includes Mitutoyo’s patented Telecentric Optical System, which reduces errors related to height variations, ensuring measurement quality even on stepped workpieces. Its durable construction supports workpieces up to 20 kg (44 lbs), accommodating larger and heavier items compared to many competitors. Advanced automation features, such as automatic outlier removal and pattern recognition, help streamline processes and reduce manual errors.

Mitutoyo’s Quick Image is also equipped for flexible measurement capabilities across a variety of materials. This adaptability makes it highly versatile, extending its usability across diverse industries handling intricate or challenging materials. Altogether, these features make the Mitutoyo Quick Image a highly competitive option for companies that prioritize reliable, accurate, and efficient vision measurement systems.

Touch, Measure, and Report with Confidence

Touch, Measure, and Report with Confidence

The QI powered by M3 represents the future of metrology, combining advanced technology with an intuitive user interface. The future of metrology is here. With M3 on Quick Image, touch, measure, and report with confidence and ease.

For industries looking to enhance precision, improve user experience, and streamline data management, the Mitutoyo Quick Image with M3 is an ideal solution. Its advanced features, coupled with its ease of use, ensure that organizations can meet their quality and compliance needs without compromising efficiency.

To learn more about what the Quick Image with M3 software and interface can do for you, visit the nearest Mitutoyo M³ Solution Center or speak with a Mitutoyo Sales Representative. You can also click below for more product information.