- I want to evaluate flat workpieces (dimensions, form)

- Position degree of holes, thin workpiece dimension measurement, micropattern evaluation, many measurement points, etc.

This is the last question!

This is the last question!

This measuring machine determines the spatial coordinates (X, Y and Z) of points or circular elements to accurately capture their position and form. It supports multiple measurements in a single unit.

Click here for details

Various image measurement technologies and software allow the system to meet diverse measurement needs. The lineup also includes multi-sensor models equipped with contact probes.

Click here for details

Supports everything from high-resolution observation to dimensional measurement through a combination with computational devices. The lineup also includes optical units such as objective lenses.

Click here for details

This is a specialized system that measures cross-sectional contours. It is useful for evaluating the cross-sectional shape of inner diameters and minute shapes of corners.

Click here for details

We provide a range of models, from portable, carry-around types to stationary models, to meet various application needs. These are useful for evaluating the surface finish of functional parts.

Click here for details

High-precision geometric shape measurement is achieved by capturing minute irregularities across the entire circumference of the cylindrical surface. It is useful for evaluating fits and high-speed rotating parts.

Click here for details

Hardness testing machines support quality control through hardness tests such as Rockwell and Vickers. Choose from a variety of machines, ranging from manual to automatic, according to your application needs.

Click here for details

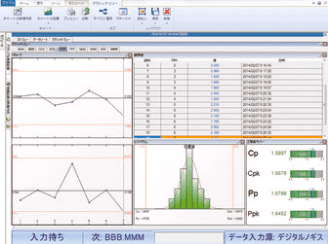

A software solution that visualizes quality by performing real-time statistical processing of measurement data. It offers robust support for preventing defects and resolving issues through comprehensive analysis of accumulated data.

Click here for details

When connected to a measuring instrument, U-WAVE wirelessly transmits the measurement results to a PC or smartphone. This helps reduce transcription errors and the manual effort required to create reports.

Click here for details